Occupational Safety, Security and Accident Prevention

Governance and Management Framework

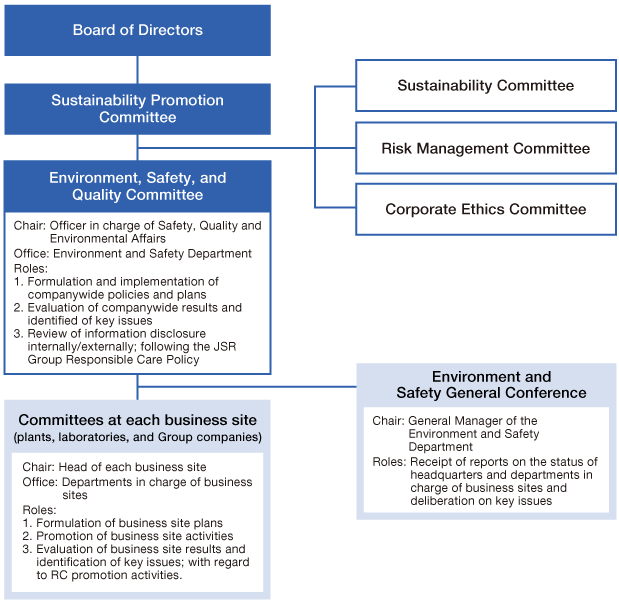

JSR Group has established an Environment, Safety, and Quality Committee as part of the Sustainability Promotion Committee to formulate the Group's safety policy and advance related activities. The chair of the committee is the officer in charge of Safety, Quality and Environmental affairs. Under the Environment, Safety, and Quality Committee, the Environment and Safety General Conference and Promotion Committees at each business site serve to advance safety activities on a company-wide and business site-specific basis.

Policy and Basic Approach

JSR Group has established a safety management system (OHSMS) at each company and business site, and it operates the system in accordance with the ISO 45001 framework. Some of our production and development sites have obtained ISO 45001 certification. Please refer to the ESG Data Book for more on certification status.

JSR Corporation has established a Safety Philosophy, a Safety Policy based on the Philosophy, and Course of Action of Safety to achieve the aims of the Philosophy and Policy. Our Philosophy defines our safety concept and value system, two core components that will never change. Our Policy lays out the direction and goals of our safety activities, and our Course of Action specifies the standards and guidelines shaping the way we conduct ourselves.

Safety Philosophy

At JSR Corporation, safety is our highest priority and the foundation of all of our activities.

Accordingly, we will create safe worksites and strive to maintain physical and mental health, with the goal of ensuring workers happily take it for granted that they will return home safely at the end of each workday.

Safety Policy

- Extremely Safe Behavior

The Safety Policy has penetrated through the organization, the Course of Action is established as applying to everyone, and safety competency is improving through proactive safety activities. - Enhanced Human Resources and Organizational Strength

High personal skills, organizational ability, and a healthy organizational culture are being maintained with the establishment and execution of the education and training programs needed for organizational management. - Optimal Risk Management and Security Measures

Security measures corresponding to risk importance are being efficiently and effectively implemented using new technologies.

Course of Action of Safety

- No matter the situation, we will act with safety foremost in mind.

- We will comply with established rules and never fail to act in accordance with safety basics.

- We will maintain safety by identifying and eliminating both actual and potential hazards.

- We will strive to create comfortable work environments and promote physical and mental health.

- Through communication and ingenuity, we will aim to achieve 100% employee participation in all safety activities.

In addition to the safety philosophies and policies at each of its companies, JSR Group formulated JSR Group's Shared Safety Concept in 2023 with the aim of improving safety levels across the entire Group. The Shared Safety Concept defines safety as “a state in which risk is at an acceptable level, with a safety infrastructure and safety culture in place.” In line with this concept, we are evaluating the safety infrastructure and safety culture of each JSR Group company and business site on a steady, continuing basis and feeding the results back into our improvement activities.

Metrics and Targets

JSR Group has set the numbers of occupational accidents and facility accidents as key performance indicators (KPIs) for safety.

| Target | Fewer than 2 occupational accidents leading to 4 or more days of absence from work and 0 major facility accidents |

|---|

| Result | |||||||

|---|---|---|---|---|---|---|---|

| Metric | Boundary | Unit | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 |

| Number of occupational accidents*1 | JSR Group | Cases | 4 | 3 | 4 | 4 | 4 |

| Number of facility accidents*2 | JSR Group | Cases | 9 | 1 | 0 | 0 | 0 |

*1 Occupational accidents that resulting in four or more days of lost time

*2 Explosions, fires, leakages, any of the following that are recognized as accidents by the government:

・Accidents or disasters that cause health hazards to employees or local residents

・Accidents or disasters with estimated damages exceeding 100 million yen

・Accidents or disasters that shut down a part of the plant for more than a month or the entire plant for more than a week

Initiatives

1. JSR Group's Shared Safety Concept

Through e-learning, we are working to disseminate JSR Group's Shared Safety Concept. The effort focused on sites in Japan in FY2023 and expanded to include locations in other countries in FY2024.

| FY | Boundary | Attendance rate | Correct response rate |

|---|---|---|---|

| 2023 | Japan (including some locations in other countries) | 89% | 89% |

| 2024 | 34 locations in other countries | 82% | 87% |

2. Establishment and utilization of safety level evaluations system

In FY2023, JSR Group has established an evaluation system for "safety infrastructure and safety culture" based on questionnaires, in order to visualize the safety level of each company and site, identify trends and issues, and turn those insights into improvements. In FY2024, we applied similar metrics to conventional environmental and safety audits to confirm that the safety-level assessment results are consistent with actual on-site conditions.

3. Centralized management of information on equipment and occupational accidents

JSR Group has a centralized framework for managing and evaluating information on equipment and occupational accidents that occur at its companies and sites. For accidents that exceeding a certain scope or level, JSR Corporation's Headquarters provide enhanced guidance to sites where such accidents have occurred and apply that effort horizontally across the company. Through these activities, we work to prevent the occurrence of similar accidents.

4. JSR Safety Day

Every July, JSR Group observes "JSR Safety Day"—an opportunity for the entire Group to look back on serious accidents, reaffirm the importance of safety, and renew its determination to prevent tragic accidents from happening again.

In FY2024, the "JSR Safety Day" event at JSR Corporation's Yokkaichi Plant on July 23 was livestreamed online to all Group companies. The event consisted of two parts: a ceremony and the Safety and Health Activities Forum. The ceremony included a message from the president, introduction of the Safety Philosophy, and introduction of company-wide safety activities. The Safety and Health Activities Forum, meanwhile, featured presentations of outstanding initiatives by Group companies. We have also put videos of the events online so that those who were unable to attend could also view them.

Safety and Health Activities Forum FY2024: Presentation topics

- JSR Group’s adaptation to safety

- Improvement activities to eradicate hazardous work at ARTON plants

- Enhancement of in-house training for thorough confirmation of environmental compliance