History

In 1957, Japan Synthetic Rubber Co., Ltd. Founded

1957

Company founded(as Japan Synthetic Rubber Co., Ltd.)in accordance with the Special Measures Law for the Synthetic Rubber Manufacturing industry.

1960s

Launching Synthetic Rubber Production in Japan

1960

Yokkaichi Plant began production and sales of butadiene,SBR,and SB latex lines.Osaka Branch was Opened.

1963

Sales of paper coating latex (PCL) began.

1964

JSR advanced into the field of synthetic resins and production of ABS resin began within the Yokkaichi Plant.

1968

The Chiba Plant was completed, and production of butadiene began.

1969

Changed company's status to private owned.

1970s

Began to Diversify the Business Portfolio while Surviving a Deep Slump

1971

The Kashima Plant was completed, and production of butadiene and SBR began.

1979

Sales of CIR (negative type photoresist) began. JSR advanced into the semiconductor materials business.

1980s

Creating New Businesses and Drive Diversification

1982

Importation and sales of optical fiber coating materials began.

1988

Sales of OPTMER AL (Alignment films for LCDs) and OPTMER SS (protective coatings for LCDs) began.

1989

Tsukuba Research Laboratory was officially opened.

1990s

Changing Corporate Name to JSR Corporation, Building a Global Production Structure

1993

UCB-JSR Electronics S.A. (Belgium) became wholly-owned subsidiary of JSR, and restarted by being renamed JSR ELECTRONICS N.V. Simultaneously JSR MICROELECTRONICS,INC. acquired U.S. operation as their subsidiary.

1996

A microphotoresist manufacturing subsidiary, JSR Electronics Kyushu Co., Ltd.(Saga) was established. Sales of epoxy type photo-curing resin having high accuracy, high-performance for photofabrication (stereolithography)

The ABS resin business was integrated with that of the Mitsubishi Chemical Corp., and a joint venture company, Techno Polymer Co., Ltd. was established.

1997

Construction work was completed for photoresist plant of JSR MICROELECTRONICS, INC.

Changed of corporate name to "JSR Corporation."

On 1997, we celebrated 40th anniversary of the founding of the company and changed our name to JSR Corporation. We had taken into consideration that our business portfolio had been expanding from synthetic rubbers and our target to expand further in the future. JSR's strategy to actively challenge to the new era, innovation and creativity had been reflected to the symbol design.

The blue square represents the universe; yellow arc represents the light before the rising sun. For JSR, the blue square means the excellence in our technology and sustainability of our company, and the yellow arc is our leading edge technology and activity. This represents our ambition to be an excellent company.

JSR will contribute to the world by technology and performance and would light the era by providing cutting edge technologies to the industry. This is what we would like to express from our symbol.

2000s

Expanding Fine Chemicals Business

2002

JSR Electronics Kyushu Co., Ltd., JSR Microelectronics, Inc. and JSR ELECTRONICS N.V. changed their names to "JSR Micro Kyushu Co., Ltd.," "JSR Micro,Inc." and "JSR Micro N.V." accordingly. Begins production of emulsion polymerization SBR consigned by Sumitomo Chemical Co., Ltd. Posts personnel dedicated to the electronic materials business in the Shanghai representative office to strengthen this business area in China.

Completes new plant facilities for semiconductor materials in Belgium.

2003

Relocates the Head Office to HAMARIKYU Parkside Place, 6-10 Tsukiji5-chome, Chuo-ku, Tokyo, Japan.

2004

JSR Micro Korea Co., Ltd (plant for production of LCD Materials) was completed and started commercial production.

2006

Completed the construction of new clean room facilities at the Yokkaichi research center.

Completed construction of precision machining pilot facilities at the Yokkaichi plant.

JSR Micro Taiwan Co., Ltd. (plant for production of LCD materials) was completed and started commercial production.

2007

Completes Yokkaichi Training center

2008

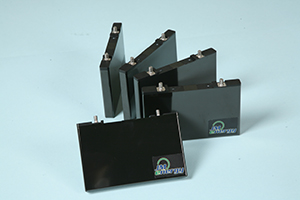

JM Energy Completed construction of world's first commercial production plant of lithium ion capacitors.

2009

Joint-venture Techno Polymer Co., Ltd. becomes 100% subsidiary.

Relocates the Head office to Shiodome Sumitomo Bldg., 1-9-2 Higashi- Shimbashi, Minato-ku, Tokyo.

JSR Starts Operations at New Plant Facilities for Cutting-edge Lithography Materials in Response to Increase in Demand for ArF Photoresists

2010s

Expanding Life Sciences Business Aiming for Sustainable Growth

2011

Completed Increase of Manufacturing Capacity of Solution Polymerization Styrene-Butadiene Rubber (SSBR)

JM Energy Completed Construction of Manufacturing Plant, Evaluation Building and Safety Assessment Laboratory for Flat Prismatic Type Lithium Ion Capacitors

Established Diagnostic Products Joint Venture called "J&W Biotech Co., Ltd." in China

2012

Completion of J&W Beijing Biotech Co., Ltd Headquarters and Plant

2015

JSR jointly acquired KBI Biopharma, Inc., a contract developer and manufacturers of biopharmaceuticals in the United States

2018

Established Techno-UMG Co., Ltd. as an integrated ABS resin business.

Started operations of JSR Elastomer India Private Limited, a new subsidiary in India.

Completed aquisition of Crown Bioscience International.

2019

Established US Headquarters for JSR Life Sciences and North America Holding Company.

2020s

Building a Resilient Organization

2021

MEDICAL & BIOLOGICAL LABORATORIES CO., LTD. (MBL) becomes 100% subsidiary.

R&D Facility, JSR Bioscience and informatics R&D center (JSR BiRD) for New Business Incubations was opened.

EUV Pioneer Inpria Corporation becomes 100% subsidiary.

2022

Elastomers Business was transferred to ENEOS Corporation

2024

Tender offer by JICC-02, Ltd. for the Company's common stock, etc. was completed; JICC-02, Ltd. became the parent company and major shareholder of the Company.

Delisted from the Tokyo Stock Exchange Prime Market.

JSR merged with JICC-02; JICC-02 changed its name to JSR Corporation and took over its business.

2025

Medical and Biological Laboratories Co., Ltd. and JSR Life Sciences Corporation are transferred to Tokuyama Corporation.