Waste Reduction

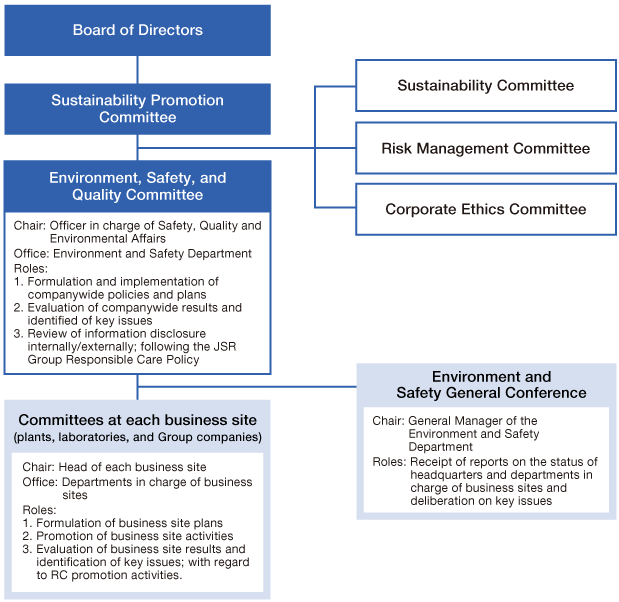

Governance and Management Framework

Based on the concept of Responsible Care (RC), JSR Group considers waste reduction to be an important issue and has established an advancement structure for the 3Rs (Reduce, Reuse, Recycle). The Environment, Safety and Quality Committee, which plays a central role in this initiative, is chaired by the officer in charge of environment, safety and quality, and the decisions of this committee are also reported to the Sustainability Promotion Committee, chaired by the CEO and President.

Furthermore, the decisions of the committee are disseminated to each business site, where specific RC activities are implemented. The status of activities is regularly confirmed by the Environment and Safety Department at JSR headquarters, which serves as the committee’s office, through the Environment and Safety Management Council and headquarters environmental and safety audits.

Policy and Basic Approach

As a manufacturer of chemical products, JSR Group understands that addressing the problem of marine plastic litter facing society is one of our most important issues. We recognize that it is our duty to contribute to the realization of a recycling-based society.

In addition to initiatives related to the 3Rs (Reduce, Reuse, and Recycle) of waste, we advance the efficient use of resources (circular economy) throughout the life cycle from raw materials procurement to product manufacturing, while also contributing to the customers through business activities and the achievement of related SDGs.

Metrics and Targets

1. Final Off-site Landfill Rate of Waste

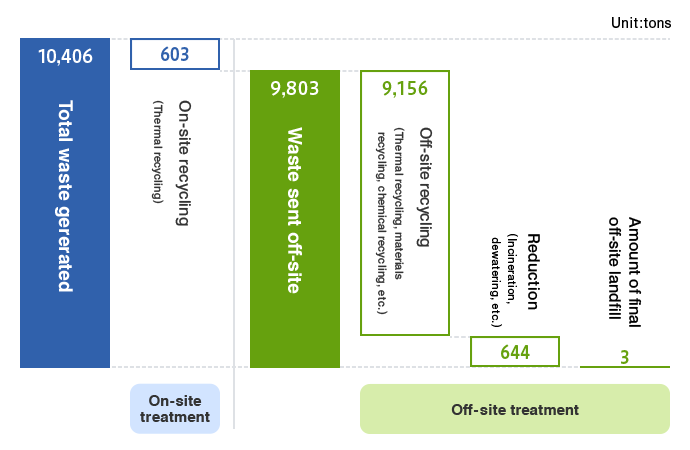

In FY2021, JSR Group set KPIs for identified materiality. In the “Environmental conservation and impact reduction” section of materiality in the Management Foundation, “Final landfill amount” is set as the KPI. We have also set an annual target of “reduce the amount of final off-site landfill to 0.1% or less of the total waste generated.” In FY2024, we achieved this target.

| Target | Final off-site landfill rate : 0.1% or less of amount of waste generated |

|---|

| Result | |||||

|---|---|---|---|---|---|

| Metrics | Boundary | Unit | FY2022 | FY2023 | FY2024 |

| Amount of final off-site landfill | JSR Group | tons | 5 | 4 | 3 |

| Final off-site landfill rate | JSR Corporation and Domestic Group Companies |

% | ≦0.1 | ≦0.1 | ≦0.1 |

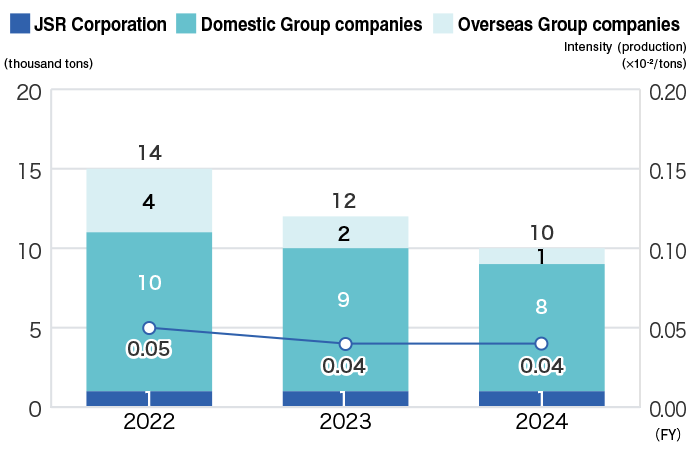

2. Amount of Industrial Waste We Generate and Recycling Rate

In FY2024, the amount of industrial waste we generated was 10,000 tons (down 11% from the previous year), and the recycling rate was 94%. Although the amount of industrial waste we generate fluctuates along with production volume, we will continue our efforts to curb the amount while promoting recycling and taking a long-term perspective in our activities.

| Result | |||||

|---|---|---|---|---|---|

| Metrics | Boundary | Unit | FY2022 | FY2023 | FY2024 |

| Waste generated | JSR Group | tons | 14,482 | 11,667 | 10,406 |

| Recycling rate | % | 92 | 90 | 94 | |

Initiatives

1. Used Plastics Recycling Advancement

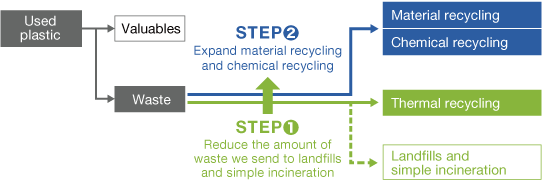

JSR Group regards the advancement of recycling as one of its key initiatives to reduce the amount of waste generated. For example, in response to the government’s Resource Circulation Strategy for Plastics, JSR Corporation has established the following FY2030 targets in FY 2019 to advance recycling.

①Achieve 100% used plastics recycling rate (including heat recovery) by 2030

②Achieve 60% used plastics recycling rate (not including heat recovery) by 2030

Initially, waste plastics were targeted, but in FY2023 the target was revised to end-of-life plastics.

The FY2024 used plastics recycling rate was 99% when including heat recovery and 55% when not including heat recovery.

As future initiatives, in Step 1, we will promote the conversion from “simple incineration” to thermal recycling (heat recovery) for industrial waste that needs to be incinerated due to its characteristics, and also promote higher-level recycling as Step 2.

| Used plastics | ||||

|---|---|---|---|---|

| Boundary | Amount generated (1,000 tons) |

Amount recycled (1,000 tons) |

Recycling rate (including heat recovery) (%) |

Recycling rate (not including heat recovery) (%) |

| JSR Corporation and Domestic Group Companies |

3.6 | 3.6 | 99 | 55 |

2. Promotion of "3R" (Reduce, Reuse, Recycle) for Packaging Materials in Logistics

JSR Corporation has always been serious about environmental measures in its logistics. Therefore, we promote "3R" (Reduce, Reuse, Recycle) to effectively utilize waste-free packaging materials and packaging containers.

We are working to reduce the weight of outer cardboard boxes (from a two-layer to a one-layer structure), as well as simplify packaging and streamline transport (palletizing) for our efforts to reduce packaging materials.

In addition, we are newly working on blank product labels, and our goal is to achieve zero waste of labels generated when product labels are reprinted. We continue to achieve zero waste with the blank labels now in use.

We are striving to use links for product containers*1 and to reuse containers used in processes for our efforts to reuse packaging materials.

Moreover, we are working to recycle various packaging materials, such as plastic drums, metal drums, pails and glass bottles, generated at our business sites for our efforts to recycle packaging materials.

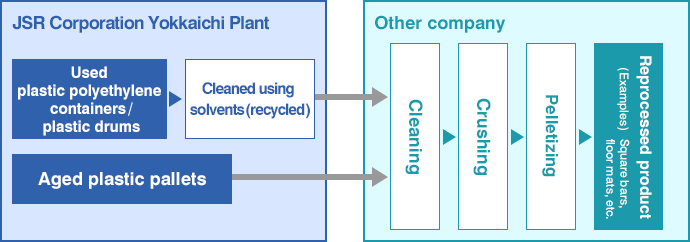

For example, used plastic polyethylene containers and plastic drums at the Yokkaichi Plant are cleaned using recycled solvents and supplied to other companies. They are recycled at these companies and transformed into new products such as square bars and floor mats. We contribute to waste reduction by recycling materials that are no longer needed and by using recycled products in the recycling process.

Also, we are making efforts to select label base materials made from recycled raw materials (foamed PET).

We will actively engage in the above 3R activities for packing materials to promote recycling and effective use of resources.

- *1Use of links: Links are returned or collected from customers for reuse.

3. Initiatives for Hazardous Waste

JSR Corporation and Domestic Group Companies properly stores and manages low-concentration PCB*2 waste in accordance with the Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes in Japan. We will also systematically carry out detoxification treatment in accordance with treatment deadlines.

- *2PCB stands for polychlorinated biphenyl