Providing Value to Society

through Our Business Activities

Contribution to Quality of Life and HappinessProviding Materials That Support a Comfortable Society

Developing Digitalization

for the Smart Society

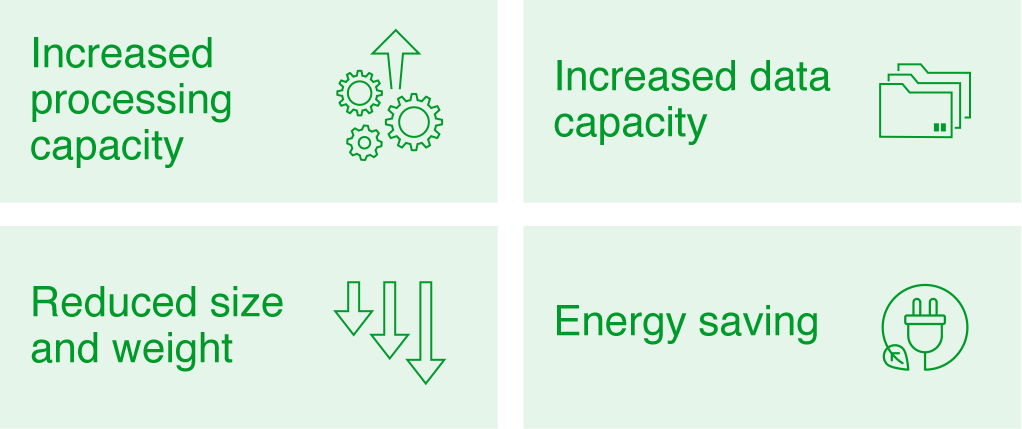

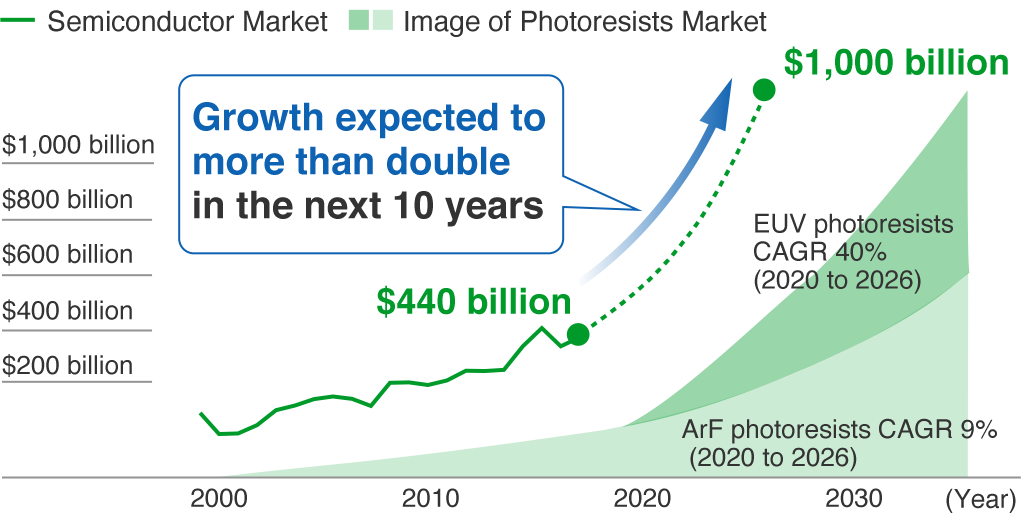

Contributing to the Miniaturization of Semiconductors with EUV Photoresists

Extreme ultraviolet ray (EUV) lithography, a cutting-edge technology used in the development of advanced semiconductors, has dramatically advanced miniaturization and further improved the degree of integration of transistors. EUV lithography, for example, has greatly enhanced the processing power of generative AI, enabling advanced data analysis and complex calculations in real time and making its use possible in ever more applications. Advances in high-speed communication technology have made data transfer from terminals to data centers even more efficient, enabling rapid processing of vast amounts of data. Furthermore, energy efficiency has improved significantly, and semiconductors that maintain high performance with low power consumption have been developed one after another, making a significant contribution to reducing environmental impact. These advances are accelerating the next generation of technologies that will support the social infrastructure of the future.

Forecast of the semiconductor market: WSTS for 2000 to 2020 and IBS from 2021 onward

Photoresist CAGR: Estimate by JSR

Contributing to the Mass Production of Advanced Semiconductors with World Class High Performance Materials Solutions

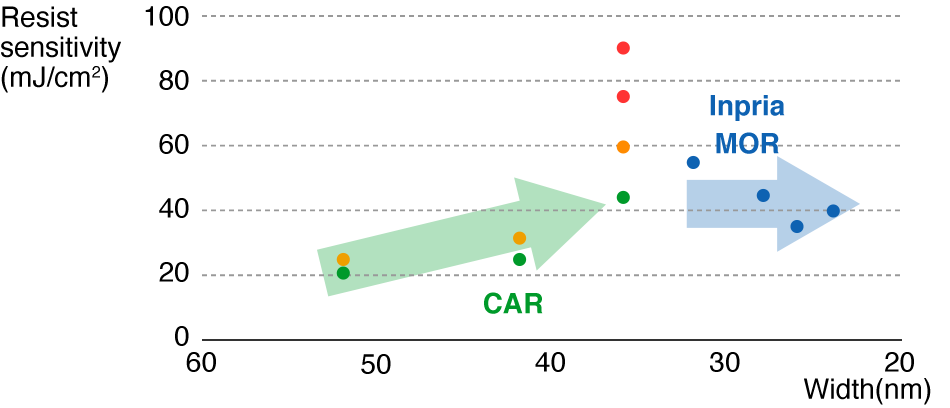

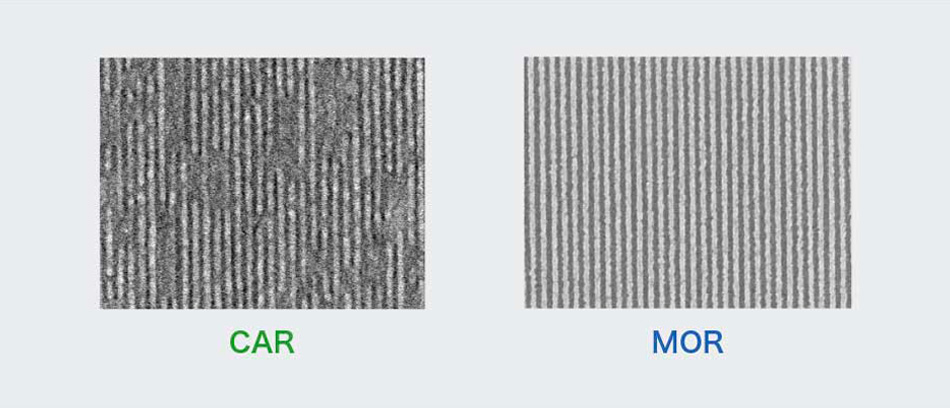

JSR acquired Inpria from which it obtained metal oxide resist (MOR) technology. This technology is one type of EUV resist that enables high resolutions. MOR has a high EUV absorption rate and excellent resolution, making it a key next-generation material that will support future miniaturization. While conventional photoresists have completely excluded metals, MOR is an innovative product that has succeeded in the high technical challenge of active metal utilization. From around 2025, MOR is expected to be applied to the mass production of actual semiconductors. This will greatly contribute to the mass production of high-performance and high-efficiency semiconductors. JSR is combining Inpria's advanced technologies with its own mass production and quality control expertise to provide competitive solutions in advanced semiconductor manufacturing processes, contributing to the evolution and technological innovation of the industry.

Financial Planning Analyst

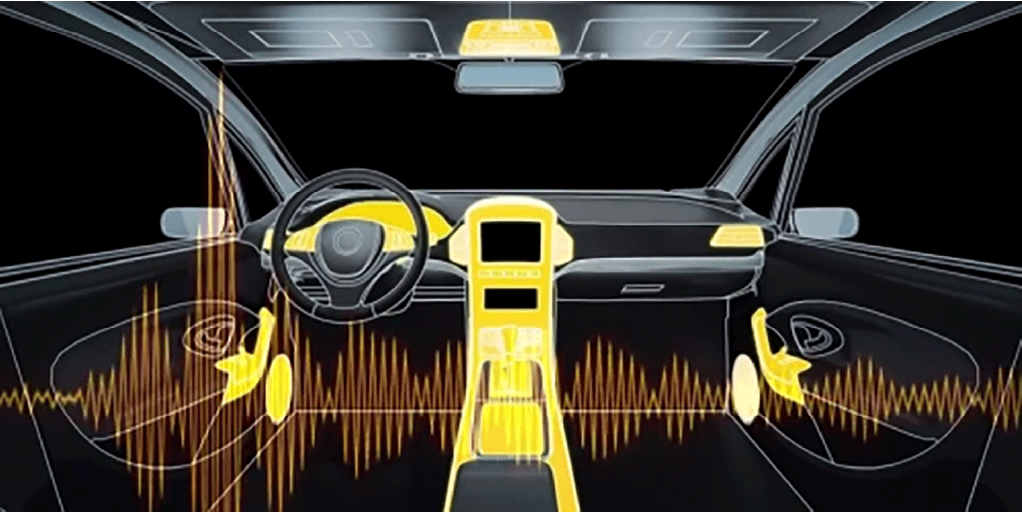

Realizing Comfortable Driving with a Reduction of Squeaks in Vehicles

Suppressing Abnormal Noises in Automobiles with HUSHLLOYTM Anti-squeak Material

EVs are spreading around the world at an accelerated pace on the back of stricter regulations to stop global warming and prevent air pollution.

On the other hand, this has led to the problem that the quietness of these vehicles means that even slight abnormal noises in them cause annoyance.

JSR Group’s HUSHLLOYTM anti-squeak material reduces the squeaks generated from the joints of plastic parts; obtaining a permanent effect that contributes to ensuring a safe and comfortable driving environment. Not only that, it also lightens the workload in terms of applying grease and affixing non-woven fabric which have been taken as measures by hand up to now.