Responsible Care Management

Responsible Care Policy

1. Policy

Seeing occupational safety, security and accident prevention, environmental conservation, and product safety as key foundations for its business activities, JSR Group conducts all business undertakings under the following Responsible Care® (RC) policy.

①We strive to ensure the safety of employees and local communities, and to contribute to environmental conservation and a sustainable global environment by ascertaining risks associated with our business activities and executing countermeasures.

②We strive to comply with laws, ordinances, and voluntary regulations by gathering information on and ensuring the full development of laws and regulations required for business activity.

③We strive to ensure the safety of our products by developing products with consideration for safety, health, and the environment and providing information about them.

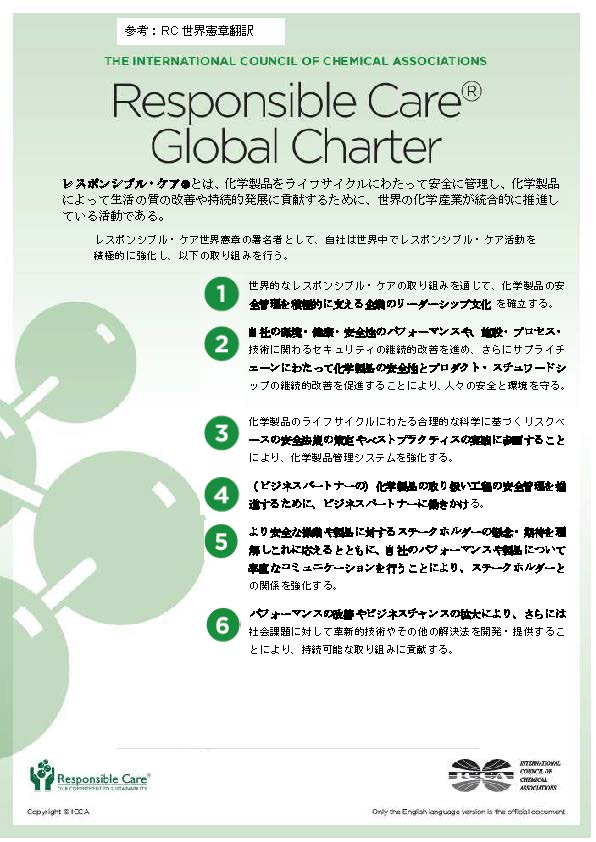

2. International Initiatives

JSR Signs Declaration Supporting RC Global Charter

The Responsible Care (RC) Global Charter is a voluntary activity policy adopted by the International Council of Chemical Associations (ICCA) and shared by the chemical industry to enhance and reinforce RC activities around the world.

JSR subscribes to this activity policy, and has signed a declaration supporting the RC Global Charter in October 2008. JSR has also signed the revised RC Global Charter in March 2015. By signing this declaration, JSR has committed itself to making even greater contributions to health, safety, and environmental preservation not just in Japan, but around the world.

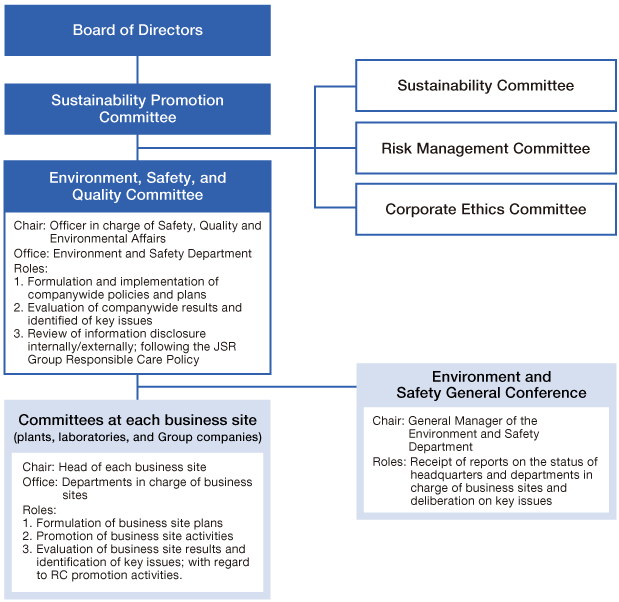

RC Advancement Structure

The Environment, Safety and Quality Committee was established to deliberate and approve JSR Group's policies, plans, activity results, and disclosed information related to the promotion of RC. In principle, the committee meets twice a year and is chaired by the officer in charge of environment, safety and quality. The committee consists of the general managers of JSR business sites and the heads of departments in charge of sustainability, environment, safety, quality, chemicals,procurement and logistics, and manufacturing and technology. The committee's decisions are also reported to the Sustainability Promotion Committee, which is chaired by the CEO, President.

The decisions of the committee are disseminated to each business site, where specific RC activities are implemented. The status of activities is regularly confirmed by the Environment and Safety Department at JSR headquarters, which serves as the committee’s office, through the Environment and Safety Management Council and headquarters environmental and safety audits.

Environment and Safety Management

1. Compliance

When laws concerning the environment and safety are adopted, enacted, or amended, the Headquarters department in charge distributes information to each business site to keep them fully informed.

JSR Group identifies laws and regulations requiring compliance based on compliance regulations and conducts annual self-checks to ensure that business departments conform with these laws and regulations.

2. Environmental Management System

As an environmental management system that supports our environmental management, JSR Corporation Yokkaichi Plant obtained ISO 14001 certification in 1999 and has kept this certification up to date each year since.

JSR Group companies, mainly manufacturing bases, have also obtained ISO 14001 certification, and are promoting environmental conservation activities using a management system that complies with this standard.

| Business site/Group company | Certification no. | Certification date |

|---|---|---|

| JSR Corporation Yokkaichi Plant | JQA-E-90119 | March 6, 1998 |

| Emulsion Technology, Co., Ltd. | NQE-0082A | June 28, 2002 |

| Techno-UMG Co., Ltd. Yokkaichi Plant | JCQA-0700 | May 15, 2000 |

| Techno-UMG Co., Ltd. Ube Plant | JQA-EM0920 | June 30, 2000 |

| Techno-UMG Co., Ltd. Otake Plant | 10408692 | March 30, 2016 |

| Japan Coloring Co., Ltd. | NQE-0004A | July 27, 1998 |

| UBE JYUSHIKAKOU, LTD. | 02842-2016-AE-KOB-JAS-ANZ | May 1, 2006 |

| JSR Micro Kyushu Co., Ltd. | JQA-EM0882 | June 2, 2000 |

| JSR Micro N.V. (Belgium) | BE04/1440.EM | May 5, 2005 |

| EUV Resist Manufacturing & Qualification Center N.V. | BE04/1440.EM | May 5, 2005 |

| JSR Micro, Inc. Sunnyvale CA(United States) | EN13339 | April 27, 2010 |

| JSR Micro, Inc. Hillsboro OR(United States) | 21554 | March 3, 2022 |

| JSR Micro Korea Co., Ltd.(Korea) | EMS 501671 | December 21, 2005 |

| JSR Micro (Changshu) Co., Ltd.(China) | 122208009 | September 3, 2019 |

3. Safety Management System

JSR Group strives to minimize risks in occupational safety, security and accident prevention by operating the PDCA cycle using a management system configured according to the circumstances of each business.

To verify the effectiveness of this management system, each business site carries out internal safety audits and patrols along with management reviews regularly every year in an effort to achieve continuous improvement.

In addition, in the unlikely event of an accident or disaster, we have compiled a manual to ensure appropriate and effective measures to prevent the spread of damage, and we conduct regular drills to ensure this system operates effectively.

The following Group companies had obtained ISO 45001 certification, a certification which they have kept up to date.

| Business site/Group company | Certification no. | Certification date |

|---|---|---|

| Techno-UMG Co., Ltd. Ube Plant | JQA-OH0037 | March 14, 2003 |

| JSR Micro Kyushu Co., Ltd. | JQA-OH0319 | March 27, 2020 |

| JSR Micro N.V. (Belgium) | BE20/819943937 | April 25, 2020 |

| JSR Micro, Inc. Sunnyvale CA (United States) | OHS13340 | April 27, 2010 |

| JSR Micro, Inc. Hillsboro OR (United States) | 18607 | March 3, 2022 |

4. Audits

Headquarters Environment and Safety Audits

The auditing team from the Environment and Safety Department of the JSR headquarters conducts annual audits of JSR Group plants and laboratories. In these audits, we conduct interviews with audited departments in accordance with the audit plan and check sheet for occupational safety and security and accident prevention, environmental conservation, and chemical management, and verify the effectiveness of the management system based on objective facts (evidence, on-site inspections, etc.).

In the effectiveness verification, we not only point out areas for improvement, but also focus on the strengths of each department. We also share the results obtained with each of the Group's business sites in an effort to improve the safety level of the entire Group.

These audits are also used as a forum for sharing and discussing issues faced by audited departments, and the Group is working as a whole to resolve issues in environmental and safety activities.

Furthermore, in audits conducted at JSR, since FY2015, we have been providing opportunities for dialogue between top management and employees to share the thoughts of both management and frontline operations, and to energize environmental and safety activities through greater mutual understanding.

| JSR Corporation (2 business sites) |

Domestic Group companies (5 companies) |

Overseas Group Companies (2 companies) |

|---|---|---|

|

|

|

5. Environment and Safety Merit Award

Environment Merit Award

At JSR Corporation, to further encourage environmental protection activities, we created the Environment Merit Award for employees who have made important contributions to environmental protection through a range of activities that include environmental product and technology development, environmental impact reduction, and assisting local communities with environment-related issues. In FY2024, a total of seven individuals received awards for three distinct achievements.

| Business site | Description |

|---|---|

| Yokkaichi Plant | Reduction of CO2 emissions through optimization of cleanroom operating conditions |

| Yokkaichi Plant | Advancement of resource recycling by changing the cleaning solvent for used plastic drums |

| JSR BiRD | Risk reduction through enhanced monitoring of research wastewater management systems |

Safety and Health Forum

JSR Group holds the Safety and Health Forum every year with the aim of raising the level of safety awareness and safety activities among employees.In 2024, the forum was held at JSR's Yokkaichi Plant, and three business sites selected from the Group in Japan gave presentations on best safety practices.

- JSR Group’s adaption to safety( MEDICAL & BIOLOGICAL LABORATORIES CO., LTD. Tsukuba Laboratory)

- Improvement activities to eradicate hazardous work at ARTON plants(JSR ARTON Manufacturing Co., Ltd.)

- Enhancement of in-house training for thorough confirmation of environmental compliance(JSR Corporation Yokkaichi Plant)

Stakeholder Engagement

As a responsible member of the local community, JSR Group participates in the Responsible Care Community Dialogue and exchanges opinions with local residents on safety management and the handling of chemical substances.