JSR Developed Antibacterial Polymeric Additive and Confirmed Antibacterial Performance by Threads/Non-woven Fabrics

JSR Corporation (Headquarters: Minato-ku, Tokyo, CEO: Eric Johnson, hereinafter "JSR") has developed, in collaboration with National Institute of Infectious Diseases, an antibacterial polymeric additive*1 that is effective against drug-resistant bacteria*2 and has further confirmed the antibacterial effect of thread and non-woven fabric made with the additive. The fabricated thread and non-woven fabric have shown to reduce Staphylococcus aureus and Escherichia Coli by 99.9% or more*3. In addition, the thread has shown to reduce the number of viruses by 99% or more*4, specifically the new coronavirus and cat coronavirus.

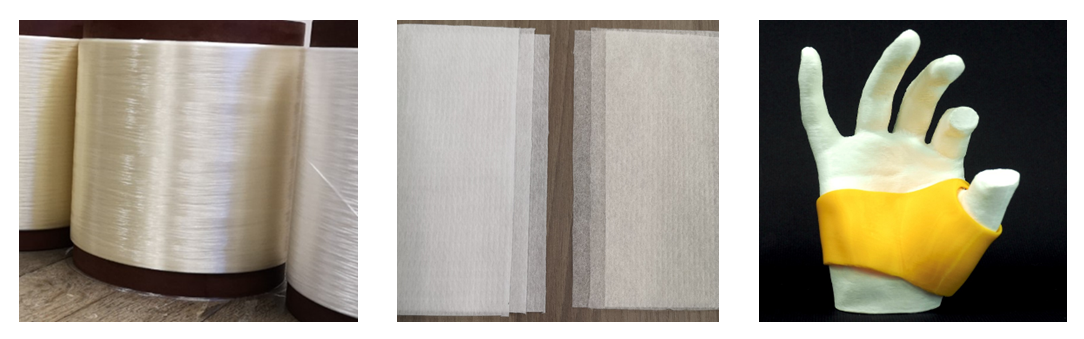

The polymeric antibacterial additive has high heat resistance and polymer miscibility for compound resins due to its amphipathic properties. These unique properties enable easy thread fabrication through several methods including spinning polypropylene multi-filaments, non-woven fabrics by melt-blown method, and films by melt extrusion. The additive can also be used for manufacturing existing general-purpose plastics (polypropylene, ABS resin, butadiene rubber, acrylic resin, polyurethane, resin for 3D printers). Consequently, it is expected to contribute to improving hygiene in medical and nursing care environments and to mitigate the potential for in-hospital infections.

In the future, an application for an SIAA*5 "Antibacterial Mark" for general-purpose plastics containing polymeric antibacterial additives is planned.

This research is supported by the Japan Agency for Medical Research and Development (AMED) under the research program on Emerging and Re-emerging Infectious Diseases by the Division of Strategic Planning and Evaluation (R&D agenda "Creation of new antibacterial drugs by reassessment of antibiotics and relocation of approved drugs”.

*1 Drug resistant bacteria

Bacteria for which antibacterial drugs are ineffective, which have become a worldwide clinical problem. Typical examples include methicillin-resistant staphylococcus aureus, vancomycin-resistant enterococci, carbapenem-resistant enterococcus bacteria, drug-resistant enterococci, and drug-resistant Acinetobacter.

*2 Polymeric antibacterial additive

Due to its amphipathic property, it can be used either as an aqueous solution, or as a plastic additive. Safety has been confirmed for acute oral toxicity (5% aqueous solution), mutagenicity, primary skin irritation, and sensitization. It was originally developed with JSR’s liquid crystal display material technology.

*3,4 Evaluation results

Evaluation was implemented in accordance with JIS L1902: 2015 at the Japan Textile Quality Technology Center.

*5 SIAAsymbol

SIAA is an antibacterial symbol established by the Antibacterial Product Technology Council (SIAA). The symbol is displayed on products that meet the three criteria; antibacterial properties, safety, and proper labeling.