JSR awarded CSJ's 64th Award for Technical Development 2015

- Development of the topcoat material used for ArF immersion lithography -

Corporate

Tokyo, Japan - March 30, 2016 - JSR Corporation (President: Mitsunobu Koshiba) is pleased to announce that the following five people have received the Chemical Society of Japan's (CSJ) 64th Award for Technical Development for the development of a topcoat material for use in ArF immersion lithography. The award ceremony was held during the CSJ's 96th Annual Meeting on the Kyotanabe Campus of Doshisha University on Saturday, March 26.

Founded in 1878, the CSJ has a history and tradition of nearly 140 years. With a membership of approximately 30,000, it is the largest chemistry-related society in Japan. Every year, the CSJ offers awards to organizations and individuals for their distinguished achievements in research, both in academia and industry. The topcoat material developed by JSR became the standard for ArF immersion lithography following commercialization in 2006. The material made the ArF immersion lithography technique practical at an early stage and helped make smaller design rules possible for Large-scale integration (LSI) circuits.

Award Recipients

Motoyuki Shima - General Manager, Semiconductor Materials Lab., Fine Electronic Materials Research Laboratories, JSR Corporation

Norihiko Sugie - Microfabrication Process Materials Lab., Fine Electronic Materials Research Laboratories, JSR Corporation

Kazunori Kusabiraki - Section I, Technical Dept. II, JSR Corporation

Hiroki Nakagawa - Semiconductor Materials Lab., Fine Electronic Materials Research Laboratories, JSR Corporation

Takashi Chiba - General Manager, R&D Div., JM Energy Corporation

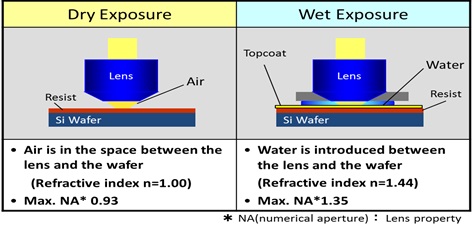

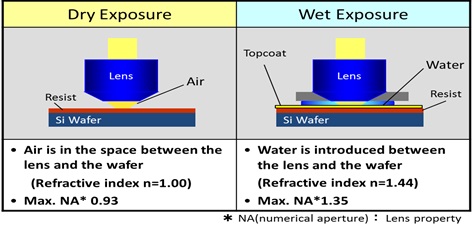

LSI circuits are at the heart of personal computers and smartphones. ArF immersion lithography is a technology designed for fine pattern exposure used in the manufacture of leading-edge LSI products (Reference 1). This technology improves lens resolution by using pure water, which has a higher refractive index than air, to fill the space between photoresist and lens. This enables transfer of patterns with finer design rules than was previously possible.

The awarded topcoat material is used to form a protective film on the photoresist before immersion exposure in order to prevent defects resulting from direct contact between the photoresist and pure water (Reference 2). Being highly water repellent, the topcoat material prevents water from penetrating the resist film and enables fast and stable operation in the ArF immersion exposure stage. Drawing on knowledge obtained through years of experience in developing photoresist and other lithography materials, JSR designed the topcoat material using a newly developed fluoroalcohol-containing polymer. Along with its water repellency, the topcoat material is soluble in the alkaline developer used to develop photoresist patterns. Consequently, the topcoat material can be removed while photoresist patterns are developed, substantially simplifying the lithography process (Reference 3).

Reference Material

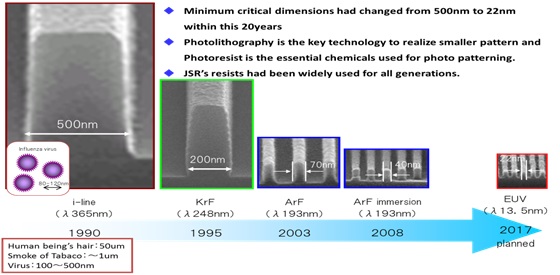

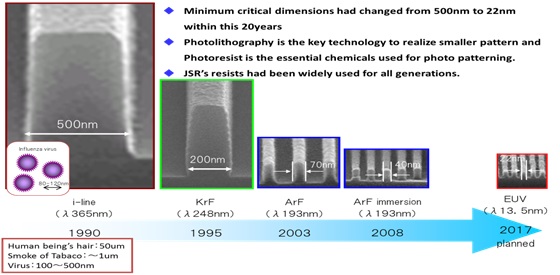

1.Improvement of resolution

2.Immersion lithography process (wet exposure)

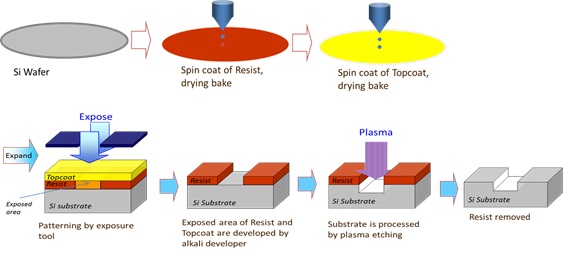

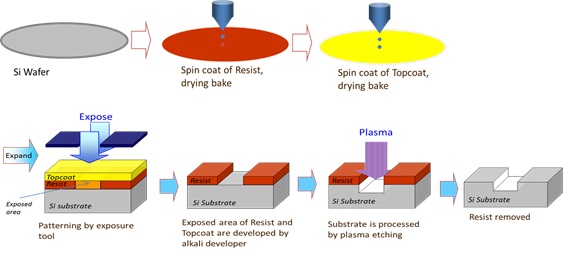

3.Example process using topcoat for ArF immersion lithography

Founded in 1878, the CSJ has a history and tradition of nearly 140 years. With a membership of approximately 30,000, it is the largest chemistry-related society in Japan. Every year, the CSJ offers awards to organizations and individuals for their distinguished achievements in research, both in academia and industry. The topcoat material developed by JSR became the standard for ArF immersion lithography following commercialization in 2006. The material made the ArF immersion lithography technique practical at an early stage and helped make smaller design rules possible for Large-scale integration (LSI) circuits.

Award Recipients

Motoyuki Shima - General Manager, Semiconductor Materials Lab., Fine Electronic Materials Research Laboratories, JSR Corporation

Norihiko Sugie - Microfabrication Process Materials Lab., Fine Electronic Materials Research Laboratories, JSR Corporation

Kazunori Kusabiraki - Section I, Technical Dept. II, JSR Corporation

Hiroki Nakagawa - Semiconductor Materials Lab., Fine Electronic Materials Research Laboratories, JSR Corporation

Takashi Chiba - General Manager, R&D Div., JM Energy Corporation

LSI circuits are at the heart of personal computers and smartphones. ArF immersion lithography is a technology designed for fine pattern exposure used in the manufacture of leading-edge LSI products (Reference 1). This technology improves lens resolution by using pure water, which has a higher refractive index than air, to fill the space between photoresist and lens. This enables transfer of patterns with finer design rules than was previously possible.

The awarded topcoat material is used to form a protective film on the photoresist before immersion exposure in order to prevent defects resulting from direct contact between the photoresist and pure water (Reference 2). Being highly water repellent, the topcoat material prevents water from penetrating the resist film and enables fast and stable operation in the ArF immersion exposure stage. Drawing on knowledge obtained through years of experience in developing photoresist and other lithography materials, JSR designed the topcoat material using a newly developed fluoroalcohol-containing polymer. Along with its water repellency, the topcoat material is soluble in the alkaline developer used to develop photoresist patterns. Consequently, the topcoat material can be removed while photoresist patterns are developed, substantially simplifying the lithography process (Reference 3).

Reference Material

1.Improvement of resolution

2.Immersion lithography process (wet exposure)

3.Example process using topcoat for ArF immersion lithography