JSR commercializes interface molecular bonding material with high adhesion New product can meet the need for high-speed communication infrastructure Expect use in further applications such as electric vehicles

TOKYO – December 13, 2022 –JSR Corporation (Headquarters: Minato-ku, Tokyo, CEO: Eric Johnson, "JSR") announced today that it has commercialized a new interface molecular bonding material called “MOLTIGHT IMB”, which enables strong bonding between different substrates, both in the process of lamination and plating. It will be exhibited at SEMICON Japan 2022, which will be held from December 14 (Wed.) to 16 (Fri.), 2022 in Japan.

“MOLTIGHT IMB” was commercialized under open innovation in cooperation with HOKOSHA TECHNOLOGIES Co., Ltd. (Headquarters: Kita-Kyushu, Fukuoka, Japan, Representative Director: Hiroshi Kuramitsu,). JSR will continue to market and develop applications for this material.

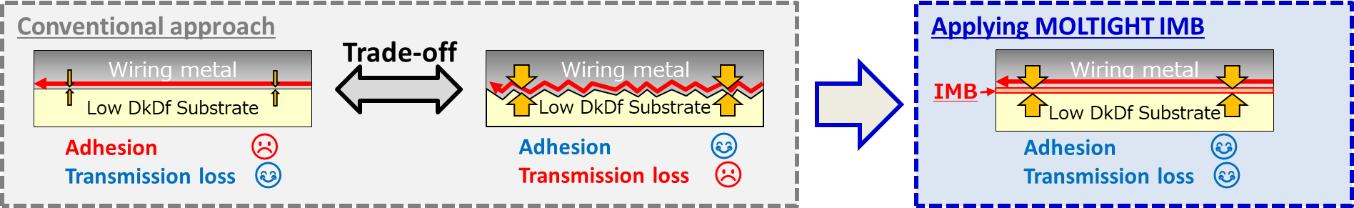

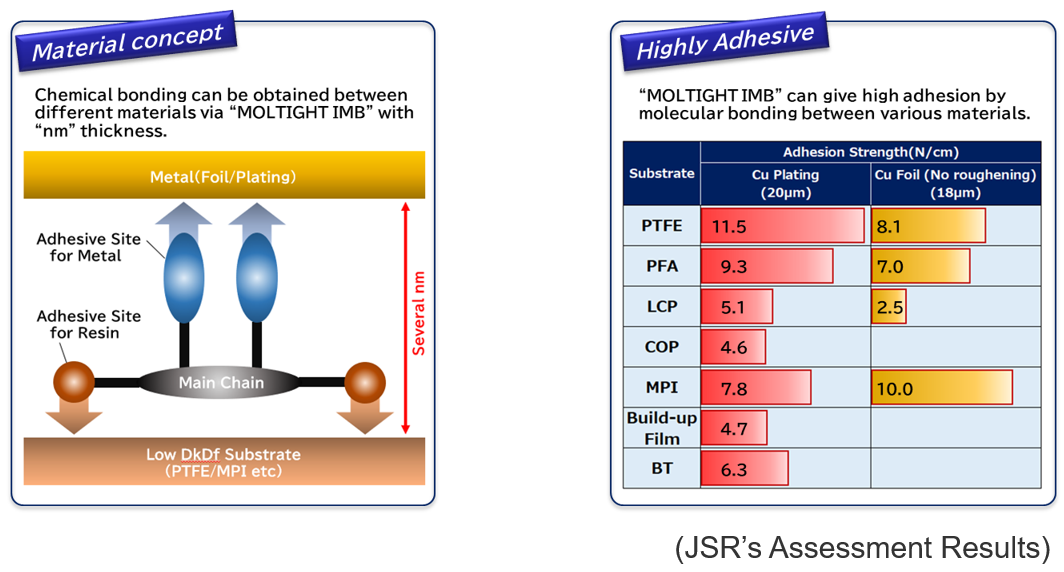

In recent years, low-dielectric tangent substrates have been used in high-speed response circuits, reflecting the growth of fifth-generation (5G), sixth-generation (6G) mobile communication systems and full-fledged autonomous driving. Conventionally, the adhesion between low-dielectric tangent substrates and wiring metals has been maintained through an anchoring effect*¹ and roughening the substrate surface. However, conductivity loss due to the skin effect occurs, which degrades the circuit's response performance. “MOLTIGHT IMB” eliminates this trade-off. This material can modify the surface of the substrate chemically at the molecular level and provide high adhesion between the substrate and the wiring metal even on a flat interface. (Figure.1, Figure.2 and Table 1) In addition, this material can strongly bond not only to metals, but also various types of substrates and form thin films of only a few nm by coating. Potential applications will be not only circuit boards, but also many others such as electrical components, batteries and sensors for automobiles and various devices.

Figure 1: Adhesion and transmission loss between low-dielectric tangent substrate and wiring metal

Figure 2: Material concept Table 1: Adhesion between substrate and copper plating and copper foil

In order to help make digital transformation possible, JSR will rapidly develop and offer solutions by utilizing our unique material design and manufacturing know-how as well as open innovation.

*¹ The effect of the adhesive getting into the uneven surface of the adherend and hardening, which increases the adhesion, as if driven in with an anchor or nail.

“MOLTIGHT IMB” is a trademark of JSR Corporation.