JSR Group Company JM Energy decides to construct High-Volume Production Plant for Lithium Ion Capacitors

10/31/2013

10/31/2013

October 31, 2013 – TOKYO- JSR Corporation is pleased to announce that JM Energy Corporation, a 100% JSR subsidiary focusing on lithium ion capacitors technology (LIC), has decided to expand its existing commercial operation with a high-volume production plant to meet the growing market demands. While the plant’s capacity will reach 3 million cells per year, the total investment amount is estimated at approximately 6 billion yen (approximately 60 million USD). The Completion of the plant is scheduled for January 2015 and first shipments to our customers from this plant are expected June 2015.

JM Energy will also start marketing its small ULTIMO™ flat prismatic-type cells. These cells are less than half the volume of our existing flat prismatic-types and will accommodate growing market needs in applications such as construction and industrial machinery and automobiles. These applications only have very limited space for the installation of additional power systems. The new plant will be capable of manufacturing all existing prismatic types as well as this newly introduced small flat prismatic type at industrial scale.

JM Energy’s LIC is an asymmetric capacitor with unique field proven performance: high power density, high energy density, and a high operating voltage. ULTIMO™ series have particularly low resistance and therefore the internal energy loss during charge-and-discharge is extremely small. JM Energy’s LIC technology also features high reliability, safety, long-term durability and a cycle performance which is equal to or greater compared to classical electric double layer capacitors (EDLC).

The newly constructed high-volume production plant will be equipped with voltage sag compensators, automatic guided vehicles (AGV) and a green energy sourced outdoor lighting system, which all will use JM Energy’s unique ULTIMO™ technology.

JM Energy’s LICs are being increasingly employed for rapid charge-and-discharge, energy regeneration, peak assist, and electrical power leveling. They have been introduced into renewable energy fields such as wind and solar power, all sorts of industrial machinery including construction machinery and momentary voltage drop compensators, medical devices and unmanned shipping devices. JM Energy’s LIC is very attractive for use in mobility applications such as automobiles, busses and trains, in order to meet the fuel efficiency and gas emission restrictions in various countries.

< Overview of Small Flat Prismatic-type Cells >

< Overview of the Commercially Available Existing Flat Prismatic-type Cells >

< Overview of the Commercially Available Existing Flat Prismatic-type Cells >

CPQ2300S

CPP3300S

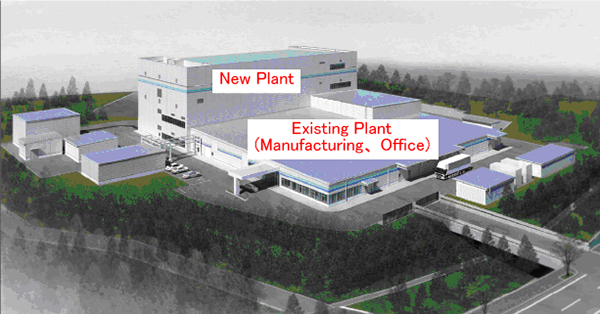

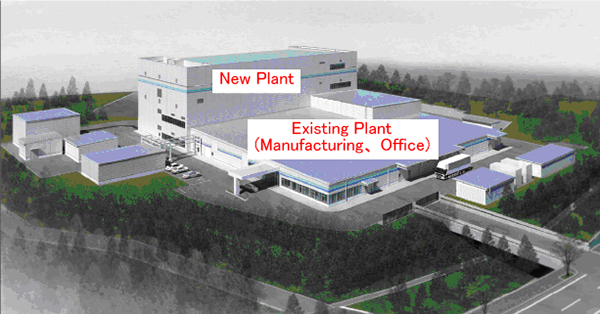

< Overview of JM Energy’s New Plant >

< Rendering of JM Energy’s New Plant >

JM Energy will also start marketing its small ULTIMO™ flat prismatic-type cells. These cells are less than half the volume of our existing flat prismatic-types and will accommodate growing market needs in applications such as construction and industrial machinery and automobiles. These applications only have very limited space for the installation of additional power systems. The new plant will be capable of manufacturing all existing prismatic types as well as this newly introduced small flat prismatic type at industrial scale.

JM Energy’s LIC is an asymmetric capacitor with unique field proven performance: high power density, high energy density, and a high operating voltage. ULTIMO™ series have particularly low resistance and therefore the internal energy loss during charge-and-discharge is extremely small. JM Energy’s LIC technology also features high reliability, safety, long-term durability and a cycle performance which is equal to or greater compared to classical electric double layer capacitors (EDLC).

The newly constructed high-volume production plant will be equipped with voltage sag compensators, automatic guided vehicles (AGV) and a green energy sourced outdoor lighting system, which all will use JM Energy’s unique ULTIMO™ technology.

JM Energy’s LICs are being increasingly employed for rapid charge-and-discharge, energy regeneration, peak assist, and electrical power leveling. They have been introduced into renewable energy fields such as wind and solar power, all sorts of industrial machinery including construction machinery and momentary voltage drop compensators, medical devices and unmanned shipping devices. JM Energy’s LIC is very attractive for use in mobility applications such as automobiles, busses and trains, in order to meet the fuel efficiency and gas emission restrictions in various countries.

< Overview of Small Flat Prismatic-type Cells >

| Size (W x H x T/mm) | : | 120.2 x 71.8 x 12.8 (excluding terminals) |

| Capacity | : | 1500F |

| Direct current resistance (DC-IR) | : | 1.2mΩ |

CPQ2300S

| Size (W x H x T/mm) | : | 150.2 x 93.2 x 15.8 (excluding terminals) |

| Capacity | : | 2300F |

| Direct current resistance (DC-IR) | : | 0.7mΩ |

CPP3300S

| Size (W x H x T/mm) | : | 150.2 x 93.2 x 15.8 (excluding terminals) |

| Capacity | : | 3300F |

| Direct current resistance (DC-IR) | : | 1.0mΩ |

< Overview of JM Energy’s New Plant >

| Construction | : | Steel construction (4 floors) |

| Total floor space | : | 8,400 m2 |

| Start of construction | : | April 2014 |

| (scheduled) | ||

| Completion of construction | : | January 2015 |

| (scheduled) | ||

| Investment amount | : | Approx. 6 billion yen (including plant structure, dry room, automated |

| warehouse and co-generation system) | ||

| Production capacity | : | 3 million ULTIMO™ flat Prismatic-type cells/year |