The Corporate Mission of the JSR Group "Materials Innovation - We create value through materials to enrich society, people and the environment".

We believe that an important role of the JSR Group is to offer innovative materials and excellent products that meet customer needs and contribute to the making of a better society.

We strive to carry out initiatives to ensure the quality and safety of our products so that our customers can use them with peace of mind.

We are able to respond to social issues through our business partners and supply chain management.

JSR constantly works to improve business processes in response to customer feedback.

Each plant has a QA Promotion Sub-Committee that works together with the Group-wide QA Promotion Committee to promote activities in accordance with corporate plans. Progress reports are presented to the Responsible Care (RC) Committee, the CSR Committee and to senior management.

Internal and quality performance audits performed by plant managers and overseen by the President or an assigned officer as well as external ISO audits are conducted on a regular basis.

All plants are ISO 9001 certified, including relevant divisions and indirect departments.

ISO 9001 certified plants:

Yokkaichi Plant, Chiba Plant, Kashima Plant, Tsukuba Research Laboratories, and relevant divisions of the Head Office

As a manufacturer, the JSR Group has responsibilities to meet the quality, cost, and supply requirements of its customers. To fulfill these responsibilities, quality performance audits have been performed annually since FY2013 in place of the previously conducted head office quality audits. These audits include reports on plant QA activity concerns such as trends and corresponding solutions of claims and other issues, and activities to improve plant capability. They also include reports on customer satisfaction levels and presentations on quality improvement activities such as Six Sigma training and small-group improvement activities. The Quality Performance Audit is promoted as one of the drivers for quality improvement activities by combining the conventional QC method with the Six Sigma method in order to achieve the best possible balance between quality, cost, and stable supply. The fourth quality performance audits were conducted under the leadership of the President in charge at JSR's three plants from January through February in 2016.

Fourth Quality Performance Audit Conducted at Yokkaichi Plant (Photo taken January 28, 2016)

Fourth Joint Quality Performance Audit Conducted at the Chiba Plant and Kashima Plant (photo taken February 12, 2016 at the Chiba Plant)

In 1994, JSR enacted its Product Liability Prevention (PLP) Standards to reinforce product safety efforts. These PLP Standards have been revised as needed to provide various stipulations for the prevention of product-related accidents at all stages of the product lifecycle, including product design, manufacturing, sales, and distribution. One example is a system for new products to be introduced to the market whereby each product undergoes safety checks starting at the product design stage, and is put on the market only after having received approval from the department manager. Similar efforts are currently being made at Group companies as well.

To prevent accidents related to products, we also strive to improve quality management throughout our supply chains - everything from raw materials procurement through distribution - by acquiring information through communication with our customers and by strengthening activities to prevent product-related accidents, such as through the revision of our quality management system and the updating of assessment technologies.

In light of recent global trends in the management of chemical substances, JSR has established the below three basic policies.

*1 Management based solely on the hazardous properties of substances

*2 Management based on exposure to the hazardous properties of substances

JSR discloses environmental and safety information to its customers by preparing a Safety Data Sheet (SDS) for all products containing polymers, regardless of whether they contain hazardous or toxic substances or not.

In Japan, our current SDS items all comply with JIS Z 7253, the Industrial Safety and Health Act, the PRTR Act, and the Poisonous and Deleterious Substances Control Act. Our new SDS electronic data management system has been in operation since its creation in 2002 to provide customers with SDS that contain the most accurate information possible about each product. This system is includes user management, chemical substance database management, creation support, and publication (revision) history. This allows us to accurately and quickly provide environmental and safety information related to JSR products.

In accordance with revisions made to the Industrial Safety and Health Act in 2014 and the subsequent ordinance proclamation by the government in June 2015, starting June 1, 2016, manufacturers are required to label chemical substances, submit the relevant SDS and conduct risk assessments. This revision significantly increases the amount and types of chemical substances subject to labeling. JSR is currently working to comply with the amended Industrial Safety and Health Act.

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) was developed as an international standard to classify and label chemicals, and includes the following elements: (a) Classification of chemical products according to danger and toxicity; (b) Labelling on product packaging and containers; and (c) Documentation and provision of details in the SDS.

In Japan, the Industrial Safety and Health Act stipulates mandatory application of GHS to the labels and SDS of products containing GHS-designated chemical substances. JSR has finished conducting danger and toxicity classification for all products that contain applicable substances and has prepared appropriate labels for its products. We have also completed the application of GHS to SDS for all our domestic products. We are currently making efforts to achieve compliance with GHS legislation in various countries and regions around the world, including the EU, South Korea, Taiwan and China.

As voluntary efforts by the chemical industry, the Japan Chemical Industry Association (JCIA), to which JSR belongs, promotes JIPS*3 and LRI*4 activities; and our company is actively involved in these programs through participation in the association's working groups and by providing research funding. We are also proactively engaged in global warming mitigation in accordance with the corresponding JCIA policy.

*3 The Japan Initiative of Product Stewardship (JIPS):

An effort to implement the Global Product Strategy (GPS), which was presented by the International Council of Chemical Associations (ICCA) at the First International Conference on Chemicals Management (ICCM-1). The aim of GPS is to attain the WSSD 2020 target, an international goal to "minimize adverse effects that the manufacturing and use of chemical substances have on human health and the environment, by 2020," which was set at the World Summit on Sustainable Development (WSSD) held in 2002. In Japan, the JCIA has promoted JIPS activities to implement GPS. Manufacturers and importers of chemical substances are working on the proper management of chemical substances in supply chains by conducting risk assessment and releasing such assessment results and other information in cooperation with companies engaged in the processing, assembly and distribution of chemical substances.

*4 Long-range Research Initiative (LRI):

The Long-range Research Initiative (LRI) is one of the critical activities of the International Council of Chemical Associations (ICCA), and is a voluntary long-term research project for chemical substances that have an impact on the environment, safety and health. Since FY2014, JCIA has been engaged in new LRI initiatives to resolve the following five issues: (1) development and evaluation of the new risk assessment method; (2) study on the safety of new chemical substances including nano materials; (3) study on the effects of chemical substances on children, the elderly, and gene disorders; (4) evaluation of the impact on ecosystems and the environment; and (5) other issues that require an emergency response.

JSR outsources the distribution of its products. To maintain environmental and safety standards during transport, JSR has drivers carry a "Yellow Card" imprinted with special measures and telephone numbers in case of emergency, in addition to having logistics companies train them on specific safety issues.

Customer feedback questionnaires are conducted every two years to obtain customer opinions on the effectiveness of our management, product development, product quality, and technical and sales support. Even though we routinely receive positive scores in product quality, and technical and sales support, we are dedicated to continually improving product quality and meeting changes in demand.

We attended the Pirelli Global Stakeholder Dialogue held on February 4, 2016 at Maison de l'Automobile in Brussels. We participated in this dialogue as a supplier to Pirelli. Through the dialogue, Pirelli wanted to gather opinions from various stakeholders, including policymakers, academia, suppliers, the financial community, customers, and NGOs, in regard to their Industrial & Sustainability Plan in effect until 2020.

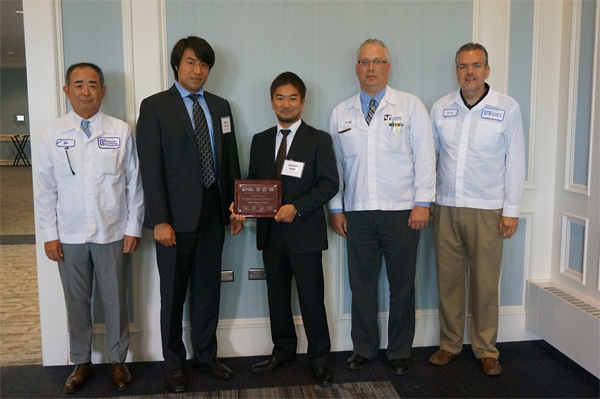

Successive recognition by Intel's Supplier Continuous Quality Improvement (SCQI) Award

SCQI Award Presentation Ceremony (Photo by Chip Holley)

We received the Supplier Continuous Quality Improvement (SCQI) Award from Intel Corporation, a world-class semiconductor manufacturer based in California, the United States. The SCQI Award is Intel's most prestigious award given to suppliers. This is the seventh time that we have received the award in the past eight years. This award serves as acknowledgment of our advanced lithography and CMP materials as well as our highly functional chemicals.

We received the best supplier award from LG Display.

Best Supplier Award presentation ceremony

LG Display (LGD) is one of two major LCD manufacturers in South Korea. In celebration of accompanied growth*5, they held a New Year's party on February 1 at the Konjiam Resort located along the Konjiam IC in South Korea. JSR President Koshiba, President Kumano and Vice President Choi Kwangsoo of JMK attended the event.

JSR received the Best Supplier Award, a commemorative plaque and a 55-inch organic LED (OLED) television as a gift.

Other attendees included LGD Vice President and CEO Han Sang-Beom, LGD Vice President and CPO Jeong Cheol-Dong, CTO Kang In-Byeong, and executives from nearly 100 domestic and international group companies. LGD discussed sustained growth due to differentiation of LCD performance, leading the premium OLED market, which is the source of new growth, and the need to establish an early competitive lead in the plastic OLED market. To this end, LGD has asked its partners to cooperate in a cost innovation project. CEO Han was stern in his determination to remain successful in this difficult business environment, an environment in which Chinese display manufacturers continue to gain market share.

Including JSR, a total of seven companies received the Best Supplier Award, including Tokyo Electron Limited, Silicon Works, Jusung Engineering, KC-Tech.

*5 Accompanied growth: Expression of the balanced growth of both major industries and partners that South Korea has experienced since 2010.

Techno Polymer America, Inc received the Delivery Performance Award from the Moriroku Group. This award is an acknowledgment of our ability to keep deadlines despite the time required to transport goods from Japan to the US, including customs processes, and issues that invariably occur. We are able to keep deadlines amidst these conditions by using alternative methods as necessary such as utilizing offices in other countries and increasing inventories.

Supply chain management is an essential component of passive CSR. We constantly look for ways to improve its effectiveness in an effort to create new value through Materials Innovation in the entire value chain.

JSR Group supply chain management has a unique feature of a chemicals manufacturer supplying materials to various industries and supporting society. Specifically, that is our ability to deliver products of discernible quality to our customers reliably and without interruption.

Supply chain management is specific to each of our businesses and so is different between the Petrochemical Products Business and the Fine Chemicals Business, or the strategic businesses. Our CSR procurement policy states that when making purchases, JSR will give sufficient consideration to legal and regulatory compliance, resource protection, environmental conservation, safety, human rights, biodiversity, and other factors that lead to a sustainable society. With suppliers understanding, and through communication, mutual understanding, and cooperation, we can continue engaging in effective initiatives. Based on Purchasing Policy and CSR procurement initiatives implemented in FY2011, we surveyed the social and environmental considerations of our suppliers using a questionnaire. When an issue was detected, we dispatched the person in charge of procurement to the supplier to work on solving the issue together. We were able to survey the suppliers that represent 99% of our purchased materials by FY2014. We will continue to coduct the same process as we establish new suppliers in the future.

Though we do not directly use raw materials associated with conflict minerals, we have been conducting investigations since FY2015 on these matters due to the potential use of such materials as catalysts used in our manufacturing processes.

JSR Engineering Co., Ltd., a JSR Group company responsible for construction work, communicates the policy of the JSR Group to the Safety Committee organized by its subcontractors and asks their cooperation in our CSR procurement initiative. CSR consciousness has been increasing among business partners, who also organize separate study meetings and discussions.

JSR has long been committed to green procurement, a policy that puts the highest priority on goods with minimal environmental impact when purchasing raw materials. In response to the growing industry trend in managing chemicals in the supply chain, JSR joined the Joint Article Management Promotion-consortium (JAMP)*6 in October 2008, and reviewed of its Green Procurement Guidelines*7. JSR will continue to practice green procurement with an emphasis on disseminating information through the supply chain.

*6 The Joint Article Management Promotion Consortium (JAMP) was established as an inter-industry organization in September 2006 to support activities that aim to create and expand specific systems for the proper management of information on chemicals in articles (components, products, and so on) and to facilitate the disclosure and dissemination of information within supply chains. JSR conducts activities that contribute to the practice of these principles through its participation in JAMP.

*7 Green Procurement Guidelines:

JSR conducted a review of its Green Procurement Guidelines when it joined JAMP. Substances presently managed at JSR were coordinated with substances managed under the JAMP MSDSplus system, and the format was changed to MSDSplus. Also, the scope of green procurement was expanded from raw materials to include packaging materials and facilities. JSR is conducting green procurement with an emphasis on the dissemination of information so it can effectively manage chemical risks in its supply chains.

JSR defines green purchasing as the purchasing of environmentally friendly office equipment and supplies not directly related to its products or manufacturing. Green purchasing is distinguished from the green procurement of raw materials for products, packaging materials, and manufacturing facilities.

The Law Concerning the Promotion of Procurement of Eco-Friendly Goods and Services by the State and Other Entities (commonly referred to as the Green Purchasing Law) was enacted in 2000, and Japan's basic policy on the law was announced in 2001, when the law came into effect. Based on this policy, JSR strives to prioritize equipment and supplies with energy-saving features and high recycled content. In FY2016, green purchasing represented 104,242 million yen out of a total of 118,931 million yen in purchases at all business sites. This is equivalent to a green purchasing rate of 88%.

We employ business continuity management (BCM) practices to manage resources to mitigate supply risk by having multiple suppliers. We also have a strict inventory management system in place based on business plans to prevent production from being halted in the event supplies of required raw materials temporarily run out.