Environment and Safety (Related Data)

Protection of the Atmospheric Environment

Boiler Emissions Countermeasures

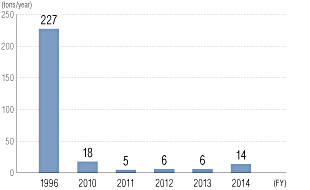

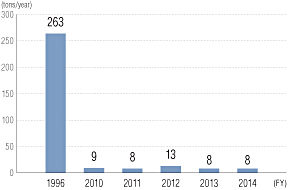

At the Yokkaichi Plant, which generates its own power, we installed flue gas desulfurizers to reduce emissions of sulfur oxides (SOx). We also substantially cut emissions of nitrogen oxides (NOx) by installing burners with low NOx emissions and denitrification equipment. SOx emissions and NOx emissions substantially reduced in FY2014 with fuel switching (from heavy oil to city gas) at the Kashima Plant (South Joint Power Plant). JSR will continue to adopt the best emissions reduction technologies and will continue to make improvements.

Regarding PRTR

PRTR*1 Activities

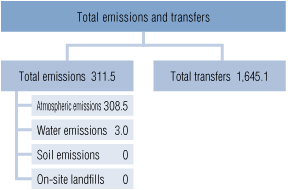

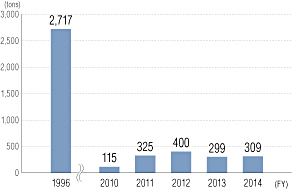

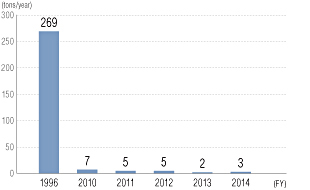

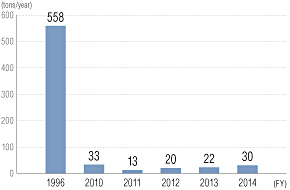

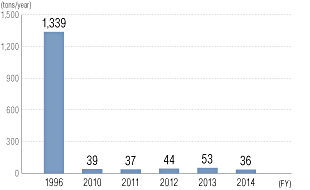

Every year, based on the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof (PRTR Act), JSR aggregates the amount of designated chemical substances released into the environment (atmosphere, water and soil) or transferred by manufacturing or used in the previous year, and notifies the government of Japan of the results. Primarily for substances that are released in significant amounts and have a great impact on the environment, we have implemented a range of measures in a planned manner, including enhancing airtightness of their release source, rendering them harmless by incineration and improving their manufacturing processes. In FY2014, as a result of taking such measures, we reduced emissions of the substances designated by the PRTR Act (309 tons) by 89% from the FY1996 level.

*1 Pollutant Release and Transfer Registers (PRTR): A system for registering the emission and movement of environmental pollutants

*2 PRTR Law: Law Concerning Reporting, etc. of Releases to the Environment of Specific Chemical Substances and Promoting Improvements in Their Management

Transferred in FY2014 (tons/year)

(Including Techno Polymer Co., Ltd. Kraton JSR Elastomers K.K. Japan Butyl Co., Ltd. Kashima Plant)

PRTR Applicable Substances

Emissions of Chemical Substances*3(PRTR Law)

| Ordinance designated number | Substance | Amounts handled*4 (t) |

Atmospheric emissions (t) |

Water emissions (t) |

Transfers*5 (t) |

|---|---|---|---|---|---|

| 1 | Zinc compounds (water-solble) | 1.629 | 0.000 | 1.629 | 0.000 |

| 2 | Acrylamide | 93.737 | 0.005 | 0.000 | 0.000 |

| 4 | Acrylic acid and its water-soluble salts | 1,264.9 | 0.000 | 0.000 | 0.000 |

| 7 | n-Butyl acrylate | 1,984.6 | 0.000 | 0.000 | 0.000 |

| 9 | Acrylonitrile | 46,662.8 | 13.851 | 0.000 | 0.000 |

| 13 | Acetonitrile | 56.9 | 0.111 | 0.591 | 2.898 |

| 20 | 2-Aminoethanol | 2.9 | 0.004 | 0.000 | 0.000 |

| 30 | n-Alkylbenzensulfonic acid and its salts (limited to those with 10 to 14 alkyl group carbons and their mixtures) |

982.2 | 0.000 | 0.000 | 0.000 |

| 36 | Isoprene | 92,860.6 | 1.093 | 0.000 | 1.013 |

| 71 | Ferric chloride | 16.6 | 0.000 | 0.000 | 0.000 |

| 80 | Xylene | 3.4 | 0.001 | 0.000 | 0.000 |

| 83 | Cumene | 18.1 | 0.183 | 0.000 | 0.000 |

| 150 | 1,4-Dioxane | 1.6 | 0.002 | 0.000 | 1.108 |

| 186 | Dichloromethane | 51.9 | 3.452 | 0.000 | 10.996 |

| 190 | Dicyclopentadiene | 14,438.1 | 0.089 | 0.000 | 39.428 |

| 202 | Divinylbenzene | 29.3 | 0.003 | 0.000 | 0.000 |

| 203 | Diphenylamine | 50.2 | 0.000 | 0.000 | 0.000 |

| 207 | 2,6-di-tert-butyl-4-cresol | 564.9 | 7.980 | 0.000 | 20.546 |

| 213 | N, N-dimethylacetamide | 2.6 | 0.043 | 0.000 | 0.014 |

| 220 | Water-soluble salts of dimethyldithiocarbamic acid | 152.2 | 0.001 | 0.000 | 0.000 |

| 234 | Bromine | 1,957.9 | 0.000 | 0.000 | 0.000 |

| 240 | Styrene | 130,581.2 | 30.417 | 0.000 | 1.538 |

| 274 | Tert-dodecanethiol | 1,025.7 | 0.067 | 0.000 | 0.000 |

| 276 | 3, 6, 9-triazaundecane-1, 11-diamine (also known as tetraethylenepentamine) |

17.4 | 0.000 | 0.000 | 0.983 |

| 300 | Toluene | 2,823.7 | 36.406 | 0.196 | 1,434.133 |

| 309 | Nickel compounds | 0.6 | 0.000 | 0.017 | 0.134 |

| 321 | Vanadium compounds | 41.6 | 0.000 | 0.000 | 40.666 |

| 330 | Bis (1-methyl-1-phenylethyl) peroxide | 17.1 | 0.000 | 0.000 | 0.000 |

| 337 | 4-Vinyl-1-cyclohexene | 120.1 | 0.000 | 0.000 | 3.770 |

| 351 | 1, 3-Butadiene | 616,927.4 | 8.492 | 0.000 | 0.911 |

| 355 | Bis (2-ethylhexyl) phthalate | 35.2 | 0.000 | 0.000 | 0.000 |

| 366 | Tert-butyl hydroperoxide | 7.7 | 0.000 | 0.000 | 0.000 |

| 392 | n-Hexane | 1,113.8 | 201.666 | 0.000 | 86.947 |

| 405 | Boron compounds | 1.3 | 0.000 | 0.544 | 0.000 |

| 415 | Methacrylic acid | 103.9 | 0.000 | 0.000 | 0.000 |

| 417 | 2, 3-Epoxypropyl methacrylate | 8.7 | 0.000 | 0.000 | 0.000 |

| 420 | Methyl methacrylate | 6,576.5 | 2.329 | 0.000 | 0.000 |

| 436 | α-Methylstyrene | 11,463.5 | 2.262 | 0.000 | 0.000 |

| 440 | 1-Methyl-1-phenylethyl hydroperoxide | 100.4 | 0.001 | 0.000 | 0.000 |

| Total | 932,162.9 | 308.5 | 3.0 | 1,645.085 | |

| 243 | Polychlorinated-dibenzo-p-dioxins*6 | - | 0.0847 | 0.0006 | 0.0790 |

*4 The handling amount shows the figure after base deduction (1 ton/year per place of business)

*5 The transfer amount is the amount committed to intermediate waste service companies plus the amount discharged into public sewers

*6 Dioxin category unit mg-TEQ

Initiatives for Reducing VOC Emissions into the Atmosphere

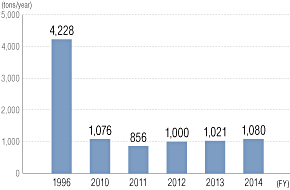

Having set a high voluntary goal of reducing emissions of volatile organic compounds (VOCs) by 75% from FY2001 levels, JSR made a large-scale investment between FY2007 and FY2010 to install five dried-synthetic rubber waste incinerators in three plants. We also carried out meticulous maintenance and management activities, including enhancing the airtightness of release points, improving the working method by adopting a closed system for chemical sampling and preventing leakage from bulbs. Consequently, VOC emissions in FY2014 totaled 1,080 tons (a 74% reduction from FY2001), which fell slightly short of our voluntary goal but nonetheless substantially exceeded both the target specified in the Air Pollution Control Act and the target set by the Japan Chemical Industry Association, with which JSR is affiliated. As we ramp up our production volume, we will maintain the level of the current voluntary goal (75% reduction from FY2001) without a large-scale investment by ensuring proper operation of dried-synthetic rubber waste incinerators and finely tuned maintenance and management.

Reference: VOC reduction targets

(1) Air Pollution Control Act (enforced in April 2006): To achieve a 30% reduction in the amount of VOCs released into the atmosphere by FY2011 from the FY2001 level with the best mix of laws and regulations, along with operators’ voluntary activities.

(2) Japan Chemical Industry Association: To achieve a 51% reduction in the amount of VOCs released into the atmosphere by FY2011 from the FY2001 level

Preservation of Water Quality

JSR performs rigorous wastewater management at all of its plants and strives to maintain and improve water quality. JSR is in full compliance with the 7th Total Pollutant Load Control that was put into operation in April 2012. We will continue to strictly monitor water quality and strive to further reduce our impact on water.

Assessment of Soil and Groundwater Pollution

Groundwater (Environmental Quality Standards for Groundwater Pollution) and soil (major items regulated under environmental standards) at all three of our plants are periodically inspected. As in previous years, no problems were found in FY2014.

Asbestos Measures

In accordance with the Ordinance on Prevention of Hazards due to Asbestos, JSR has conducted checks at all of its facilities (office, manufacturing, R&D and employee amenity areas), including those of all Group companies, where asbestos containing materials have been sprayed. Subsequently, at locations in plants where asbestos was found, we completed removal and enclosure projects in FY2007. In addition, we are investigating the replacement of asbestos containing gaskets with non-asbestos containing types and are progressively carrying out replacements when the safety of their use in production has been confirmed.

The Air Pollution Control Act and the Ordinance on Prevention of Hazards due to Asbestos were amended on June 1, 2014 to prevent asbestos from spreading in the atmosphere, and accordingly, regulations concerning building demolition work were tightened. In accordance with these amended laws, we will continue to act properly to prevent workers engaged in building demolition from acquiring health problems caused by asbestos exposure.

In order to accommodate requests from the Labour Standards Bureau of the Ministry of Health, Labour and Welfare to thoroughly inform our employees of various systems, including the issuance of the asbestos-related health care handbook and the provision of special benefits as industrial workers' compensation for bereaved families, we introduced the relevant leaflet released by the Ministry of Health, Labour and Welfare on our website.

PCB Management

In accordance with the Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes, JSR strictly stocks and manages PCB waste. We have progressively been rendering it harmless as shown in the table below.

| FY2014 | Number of devices | Oil containing PCB (liter) | |

|---|---|---|---|

| Electrical devices | Devices in storage (not in use) | 107 | 74,994 |

| Devices in operation | 0 | 0 | |

| Total | 107 | 74,994 | |

| Total number of devices treated | 209 | 110,473 | |

| Current treatment status (%) | 66.1 | 59.6 | |

Measurement of Ozone-depleting Substances

In 1994, JSR eliminated all use of carbon tetrachloride. By FY2011, all CFCs contained in large-scale designated equipment at our manufacturing facilities were replaced by chlorofluorocarbon substitutes.

Environment Merit Award

To further encourage environmental protection activities, we created the Environment Merit Award for people who have made an important contribution to environmental protection through any of a range activities that include environmental product and technology development, environmental impact reduction, and assisting local communities with environment-related issues. Nine employees received this award for three areas of excellence in FY2014.

Environment Merit Award| Case | Description | |

|---|---|---|

| Yokkaichi Plant | Reduction of CO2 emissions through optimized operation of the power generator | Efficient operating conditions of the boiler-turbine generator unit were standardized, resulting in an approximate 10,700 tons/year reduction in CO2 emissions. |

| Yokkaichi Plant | Reduction of COD load in wastewater through optimized operation of the wastewater lagoon | Operation of the wastewater lagoon was improved such that the COD load in wastewater was efficiently lowered by approximately 16%/year. |

| Chiba Plant | Reduction of waste ARTON resin | A technique to turn non-standard ARTON resin, which until then had simply been disposed of, into valuable materials was established in cooperation with Group companies, resulting in an approximate 147 tons/year reduction in the amount of waste generated. |

Environmental Accounting

■ JSR Independent AccountingJSR introduced environmental accounting in FY2000 with the following two objectives

1. To strive to quantify the amount of resources invested into the environment and implement sound measures for the environment.

2. To publish environmental accounting and increase corporate transparency.

JSR Head Office, Yokkaichi Plant, Chiba Plant, Kashima Plant and Research Laboratories (including JSR Life Sciences Corporation)

■ Target PeriodApril 1, 2013 - March 31, 2014

■ UnitMillion yen

Underlying Assumptions regarding Aggregation and Calculation

1. While costs were mainly calculated based on actual results, some expenses were calculated based on underlying assumptions.

2. Economic effects were substantial and did not include conversions of risk aversion effects or deemed effects into monetary amounts.

Environmental Protection Costs

| Category | Details of implementation (figures in parentheses are in millions of yen) |

Investment*1 | Expense | |||

|---|---|---|---|---|---|---|

| FY2013 | FY2014 | FY2013 | FY2014 | |||

| (1) Business area costs | 739 | 555 | 4,621 | 3,891 | ||

| Breakdown | (1)-1 Pollution prevention costs |

Investments: Reduction of toxic atmospheric pollutants and measures to prevent atmospheric pollution (74), water pollution control measures (168), measures to prevent odors (99), etc. Expenses: Operation maintenance cost, depreciation expenses, etc. water quality (479), odor (553), etc.) |

(167)*2 | (344)*2 | (1,870)*2 | (1,356)*2 |

| (1)-2 Global environmental protection costs |

Investments: On-site power generation (113), energy-saving measures (24) Expenses: Operational maintenance cost, depreciation expenses, personnel expenses (821), etc. |

(466)*2 | (163)*2 | (1,089)*2 | (943)*2 | |

| (1)-3 Resource circulation costs |

Investments: Renovation of the ancillary facilities of industrial waste incinerators (43), etc. Expenses: Maintenance of industrial waste incinerators (944), industrial waste recycling (158), etc. |

(106)*2 | (48)*2 | (1,662)*2 | (1,592)*2 | |

| (2) Upstream/downstream costs | 0 | 0 | 0 | 0 | ||

| (3) Management activity costs | Investments: Renovation of analysis equipment (6), etc. Expenses: Maintenance of monitoring and measuring systems (81), maintenance of ISO 14001 (57), greening and preservation (35), etc. |

167 | 10 | 438 | 467 | |

| (4) Research and development costs | Expenses: Development of environmentally considerate products (1,440), registration of new chemical substances (170), etc. | 0 | 0 | 1,501*3 | 1,670 | |

| (5) Social activity costs | Expenses: Environmental activities (25), support for ICETT (16), JSR’s burden charge for environmental groups (7), etc. | 0 | 0 | 43 | 52 | |

| Total | 906 | 565 | 6,603 | 6,080 | ||

*1 Refers to the amount of the orders placed

*2 Figures in parentheses indicate breakdowns of the totals

*3: Corrected from the figure disclosed last year (1,504)

| Item | Cost (million yen) | |

|---|---|---|

| FY2013 | FY2014 | |

| Total amount of investments for the period*4 | 9,300 | 8,850 |

| Total amount of research and development costs for the period | 16,500 | 16,500 |

*4 Refers to the amount of the orders placed

Note: The total amount of investments increased in FY2013 due to the implementation of large projects to combat global warming and promote energy conservation, but returned to normal in FY2014.

Environmental Protection Effects

| Effect | Index | Unit | FY2013 | FY2014 | Year-on-year improvement*5 | Related information |

|---|---|---|---|---|---|---|

| Environmental effects related to resources used in business activites | Energy use (crude oil equivalent) | kℓ | 275,400 | 267,500 | -7,900 | For more information |

| Use of resources designated under PRTR law | tons | 964,600 | 932,200 | -32,400 | For more information | |

| Water resource use | Thousand square meters | 15,200 | 15,100 | -100 | For more information | |

| Environmental protection effects related to environmental impact and waste discharged from business activities | CO2 emissions | tons | 706,200 | 645,500 | -60,700 | For more information |

| SOx emissions | tons | 27 | 5 | -22 | For more information | |

| NOx emissions | tons | 415 | 328 | -87 | For more information | |

| PRTR substance emissions | tons | 303 | 312 | 9 | For more information | |

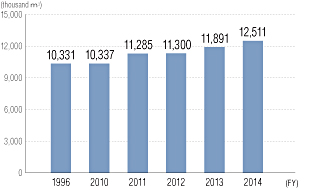

| Wastewater | Thousand square meters | 11,891 | 12,511 | 620 | For more information | |

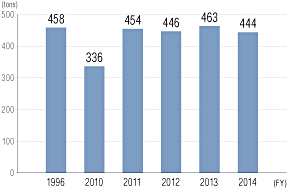

| COD emissions | tons | 463 | 444 | -19 | For more information | |

| Total nitrogen emissions | tons | 145 | 147 | 2 | For more information | |

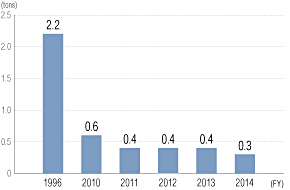

| Total phosphorus emissions | tons | 0.4 | 0.3 | 0 | For more information | |

| Waste materials from plants | tons | 23,791 | 23,535 | -256 | For more information | |

| Waste recycled offsite | tons | 21,739 | 22,118 | 379 | For more information | Reduced volume of waste treated offsite | tons | 2,045 | 1,416 | -629 | For more information |

| Waste materials from plants disposed of by landfill | tons | 7.0 | 0 | -7.0 | For more information | |

| PRTR materials transported | tons | 2,451 | 1,645 | -806 | For more information | |

| Other environmental effects | Products transported | million ton-kilometer | 471 | 492 | 21 | For more information |

| CO2 emissions during transport | tons | 21,900 | 22,960 | 1,060 | For more information | |

| Environmental complaints (odor, noise, vibration) | cases | 0 | 0 | 0 | For more information |

*5 Improvement from the previous years has not been corrected in terms of the production volume

Economical Effects of Environmental Protection Measures*6

| Effect (for one year) | Benefit | ||

|---|---|---|---|

| FY2013 | FY2014 | ||

| Cost reduction | By saving energy | 386 | 142 |

| By saving resources | 215 | 174 | |

| By treating waste on-site | 0 | 288 | |

| Total | 601 | 604 | |

*6 The economical effects of energy saving and resource saving compared to the previous year

Consolidated Accounting for Group Companies

| Investments | Expenses | Benefit | ||||

|---|---|---|---|---|---|---|

| FY2013 | FY2014 | FY2013 | FY2014 | FY2013 | FY2014 | |

| JSR | 906 | 565 | 6,603*7 | 6,080 | 601 | 604 |

| Total of 14 Group companies | 110 | 130 | 2,334 | 2,242 | 362 | 494 |

| Total | 1,016 | 695 | 8,937*7 | 8,322 | 963 | 1,098 |

*7 Corrected from the figures disclosed last year (Expenses in FY2013: JSR (6,606), Total (8,940))

Development of New Environmental Protection Technologies

Amount of Capital Investment

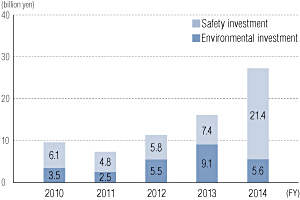

JSR makes continuous investments in the environment and safety. Investments made in FY2014 reached 2.7 billion yen. This consisted of investments in plant and facilities aimed at various environmental improvements such as energy-saving equipment, and safety improvements such as full-scale anti-seismic measures. JSR will continue to make ambitious investments to maintain and improve the environmental, safety, and health aspects of operations in accordance with its medium-term capital investment plan.

- Large-scale, natural gas-fired turbine cogeneration system (FY2010)

- Full-scale anti-seismic measures for facilities (FY1996-2014)

- Ground flare installation (FY2000, FY2008)

- Renovation of sludge dehydrator and upgrading efficiency (FY2001)

- Facilities to reduce hazardous atmospheric pollutants (FY1999-2008)

(dichloromethane solvent recovery facilities, 1,3-Butadiene treatment facility, incinerators for dry synthetic rubber dry exhaust, etc.) - Augmented comprehensive facilities to treat wastewater (FY2006, FY2008)

- Sludge dryer system (FY2013)

Main Areas of Environmental & Safety Capital Investment

(Year in parentheses is investment year)

Development of New Environmental Protection Technologies

Guided by the company's environmental concept that "technological breakthroughs enhance environmental protection," JSR, led by its Process Development Center, is actively engaged in the development of new technologies to promote environmental protection. The following are recent themes in technological development approached by JSR. We deploy technologies as they are developed.

- Computer-assisted optimization of heat recovery (pinch technology)

- Computer-assisted optimization of energy use in control systems

- Energy-saving through changes in heat recovery and solvent types across multiple plants 2. Other Technologies to Reduce Environmental Impact

- Development of solution polymerization manufacturing facilities and a new solvent recovery process (to reduce hydrocarbon emissions into the atmosphere)

- Development of synthetic rubber manufacturing facilities and dry exhaust systems (to reduce odors near plants and hydrocarbon emissions into the atmosphere)

- Development of polymerization technologies to combat total nitrogen emissions (measures to prevent eutrophication of ocean waters)

- Development of environmental technology through more effective use of microbes (to reduce odors near plants and to improve the quality of wastewater)

- Incineration technology for dry synthetic rubber dry exhaust (measures for harmful atmospheric pollutants)

- Installation of a sludge dryer system (to reduce CO2 emissions and promote effective utilization of waste)

Main Areas of Environmental & Safety Technology Development

-

1. Development of Energy-saving Processes

Improving the Local Environment

Dried-synthetic rubber waste incinerator (Kashima Plant)

Dried-synthetic rubber waste incinerator (Kashima Plant)

JSR values the opinions of local residents and considers high transparency of plant operations to be the key to improving the local environment. With this in mind, we have strived to improve the local environment by implementing monitoring and tours of environmental equipment at regular intervals. In FY2007 and 2008, we installed equipment to incinerate dry synthetic rubber dry exhaust (RTO*8) at the Yokkaichi, Kashima, and Chiba plants to prevent foul odors. In FY2009, a ground flare was installed at the Yokkaichi Plant to prevent noise and flashes, and as a result there were no environmental complaints from FY2009 to FY2014. We will continue to strive to maintain our basic policy of improving the local environment.

*8 RTO (Regenerative Thermal Oxidizer): A device that combusts VOCs and breaks them down into water and CO2 to make emissions clear

Improvement Initiatives

Odor: Emissions incinerator

Noise: Ground flare

Ground flare

Ground flare (Yokkaichi Plant)

List of Major Environmental and Safety Awards

JSR was recognized for its leadership on the environment and safety with the following awards.

| 1979 | Kashima Plant | Japan Chemical Industry Association (JCIA) | Safety Award |

|---|---|---|---|

| 1982 | Yokkaichi Plant | Japan Chemical Industry Association (JCIA) | Safety Award |

| 1986 | Chiba Plant | Minister of International Trade and Industry | Outstanding High-Pressure Gas Plant |

| 1989 | Yokkaichi Plant | Minister of International Trade and Industry | Outstanding High-Pressure Gas Plant |

| 1991 | Chiba Plant | Minister of Labor | Progress Award (in the safety category) |

| 1992 | Kashima Plant | Minister of International Trade and Industry | Outstanding High-Pressure Gas Plant |

| 1993 | Yokkaichi Plant | Director-General, Fire Defense Agency | Fire Defense Award |

| 1993 | Kashima Plant | Minister of Labor | Progress Award (in the safety category) |

| 1994 | Chiba Plant | Director-General, Fire Defense Agency | Fire Defense Award |

| 1994 | Kashima Plant | Director-General, Fire Defense Agency | Fire Defense Award |

| 1995 | Chiba Plant | Minister of Labor | Award for Excellence (in the safety category) |

| 1995 | Kashima Plant | Minister of Labor | Award for Effort (in the safety category) |

| 1999 | Chiba Plant | Japan Chemical Industry Association (JCIA) | Safety Award |

| 2002 | Chiba Plant | Minister of Health, Labor and Welfare | Award for Effort (in the health category) |

| 2003 | Yokkaichi Plant | Chubu Bureau of Trade, Economy and Industry | Award for Excellent Energy Management Plant (Thermal Sector) |

| 2006 | Tsukuba Research Laboratories | Director-General, Fire Defense Agency | Fire Defense Award |

| 2007 | Yokkaichi Plant | Japan Responsible Care Council (JRCC) | Responsible Care Award |

| 2010 | Chiba Plant | Japan Chemical Industry Association (JCIA) | Award for Safety Excellence |

| 2012 | Yokkaichi Plant | Japan Chemical Industry Association (JCIA) | Most Excellence Award for Safety |

| 2013 | Chiba Plant | Japan Chemical Industry Association | Responsible Care Award |

| 2013 | JSR Optic Tsukuba | Director-General, Fire Defense Agency | Fire Defense Award |

| 2013 | JSR Micro Kyushu | Director-General, Fire Defense Agency | Fire Defense Award |

| 2013 | Japan Coloring | Chubu Bureau of Trade, Economy and Industry | Award for Excellent Energy Management Plant |