Initiatives to Prevent Global Warming

Initiatives Aimed at Preventing Global Warming

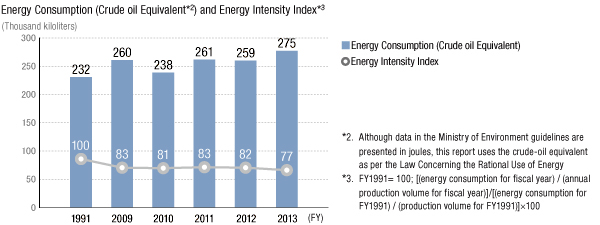

Energy Consumption

JSR's Responsible Care Committee adopted a Medium-Term Voluntary Environmental Preservation Plan. This plan sets targets regarding energy intensity for reducing energy use as measures to prevent global warming. To achieve them, JSR is carrying out the E-100 plus project at all of its Group companies to reduce energy and resource consumption. In FY2013, we were able to achieve the energy intensity targets, as we did in FY2012. We will continue to focus on the targets and make further efforts to conserve energy.

Energy Reduction Targets

Reduce energy consumption per unit of production by an average of 1% per annum, using FY1999 as the base year (voluntary standard based on the revised energy conservation law*1)

(The standard has been maintained since FY2013.)

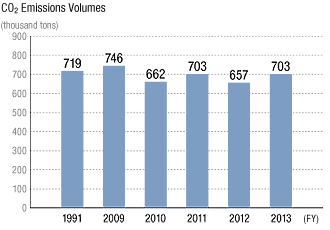

Reducing Carbon Dioxide Emissions

JSR set a CO2 emission reduction target under the Medium-Term Voluntary Environmental Preservation Plan and is striving to meet this target through various energy saving activities.

CO2 emission reduction target

Establish a system during FY2013 that enables a 6% reduction in total CO2 emissions from the three plants compared to FY1991

(Achieve the 6% reduction target in FY2014.)

In FY2013, we were committed to upgrading our energy saving technologies through such measures as fuel switching at the Kashima Plant (Kashima South Joint Power Corporation) and the introduction of a sludge dryer system at the Yokkaichi Plant, and achieved the target of establishing a system “that enables a 6% reduction in total CO2 emissions from the three plants compared to FY1991.” However, although these efforts were initially expected to lead to a reduction in CO2 emissions by 5.1% compared to FY1991, in FY2013, the actual reduction was only about 2.2% due to the shutdown of nuclear power stations after the Great East Japan Earthquake, increased production, and other factors. In FY2014, implementation of fuel switching at the Kashima Plant (Kashima South Joint Power Corporation), full fledged operations of the sludge dryer system at the Yokkaichi Plant, and other measures to be taken are expected to bear fruit, resulting in an approximately 7.1% reduction in CO2 emissions compared to the base year FY1991.

Examples of measures taken to reduce CO2 emissions| Example 1: Introduction of a natural gas-fired turbine cogeneration system | |

|---|---|

| The Yokkaichi Plant installed a natural gas-fired turbine cogeneration system in April 2010. By using natural gas as fuel, this system helped us to cut CO2 emissions by approximately 29,000 tons in FY2013 compared to emissions using the previous coal and heavy oil-fired steam boiler and condensing steam turbine system. |

|

| Example 2: Introduction of a sludge dryer system that makes sludge combustible | |

| The Yokkaichi Plant installed a sludge dryer system in December 2012. Sludge generated from the wastewater treatment facilities at the Yokkaichi Plant was previously dried to a water content of 80% before being burned in two incinerators. However, high heat (around 800℃) is necessary for incineration of sludge with a water content of 80%, thus requiring a combustion support fuel (heavy oil). The sludge dryer system introduced in FY2013 is capable of drying sludge to a water content of only 20%, making sludge combustible without the need for any combustion support fuel. The system also reduces sludge volume to about one fifth, eliminating the need for one incinerator. The system is thus expected to help us to reduce CO2 emissions by approx. 15,000 tons annually. |

|

Logistics Environmental Policy

Improving Transport Efficiency

As part of our environmental efforts in transportation, we have taken systematic steps to reduce our energy use in transportation as a designated shipper under the FY2007 amended Energy Conservation Law. We are trying to reduce transport energy intensity by at least an average of 1% per annum by using larger tanker trucks and shifting from road to rail and water transport. In FY2013, we continued to promote a shift from road to rail and water transportation for products and raw materials. However, energy intensity was maintained at the same level as the previous year due to a decline in the percentage of transport by ship caused by a decreased volume of material transportation.

Nonetheless, we were able to reduce transport energy intensity by 5.6% compared to FY2007.

| FY | 2009 | 2010 | 2011 | 2012 | 2013 |

|---|---|---|---|---|---|

| Transport volume (1 million ton-kilometers*4) | 480 | 427 | 479 | 473 | 471 |

| Rail/Sea transport ratio (%) | 84 | 85 | 84 | 83 | 82 |

| Energy consumption level (kiloliters: converted to crude oil) |

8,780 | 7,681 | 8,729 | 8,726 | 8,655 |

| Energy intensity (kiloliters/1,000 ton-kilometers*4) |

0.0183 | 0.018 | 0.0182 | 0.0184 | 0.0184 |

| CO2 emission level (tons) | 22,400 | 19,600 | 22,100 | 22,200 | 21,900 |

*4 Ton-kilometer: Freight Tonnage (Ton) × Transport Distance (km)